Choose Your Login Account

Thomson currently has two account systems - one for the website and CAD model downloads, and one for e-commerce. We understand that two logins is an inconvenience and are working to consolidate our systems into one login process. Until we’re able to consolidate the two logins, please follow these guidelines:

- Download CAD models

- Save and retrieve projects in LinearMotioneering® and MicronMotioneering® tools

- Access Distributor Extranet and all related resources

- Order directly from Thomson online (North America only)

- Authorized Thomson Distributors can view and order from quotes online (Global)

- View the shopping cart and look up prior direct orders

개요

Why Choose Ball Screw Assemblies?

Ball screw assemblies provide an excellent method for translating rotational motion to linear motion for many applications, including those where high loads and close tolerances are required. To apply the correct type of ball screw and nut assembly in a particular application, the design engineer must consider the advantages and capabilities of each. Selecting the right technology can reduce design complexity, improve performance and reduce the overall cost of the assembly.

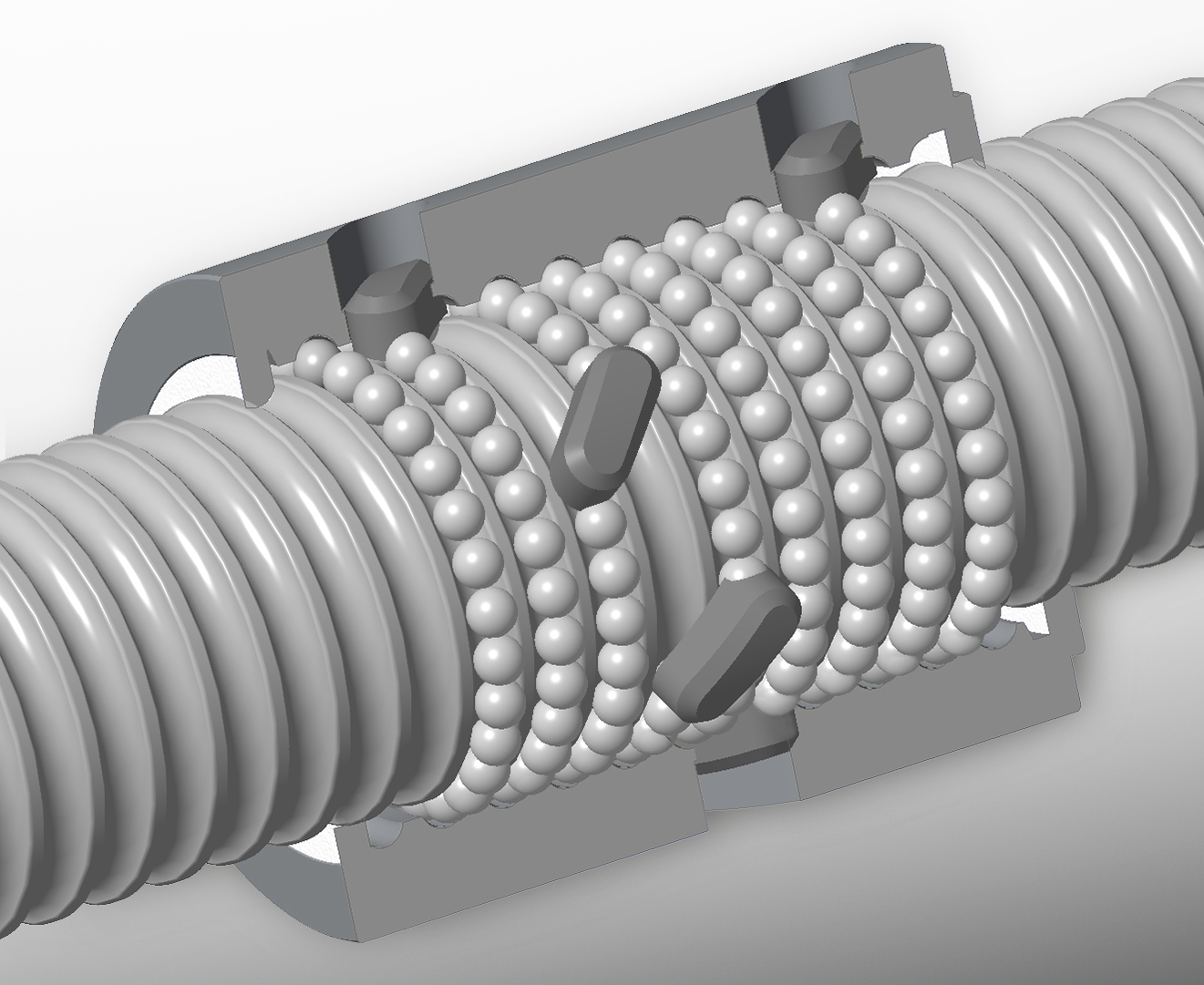

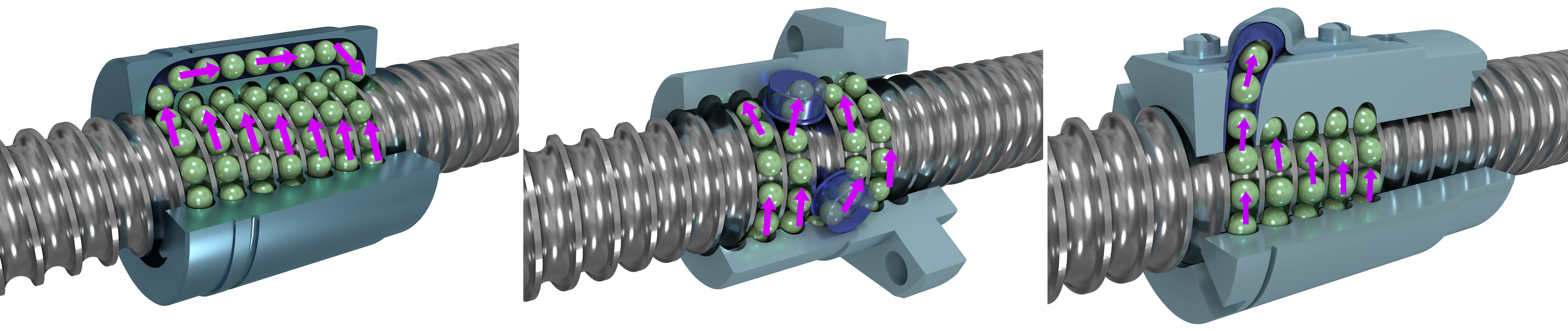

This image compares the three types of ball return systems (from left to right): internal, button and external.

Mounting Options

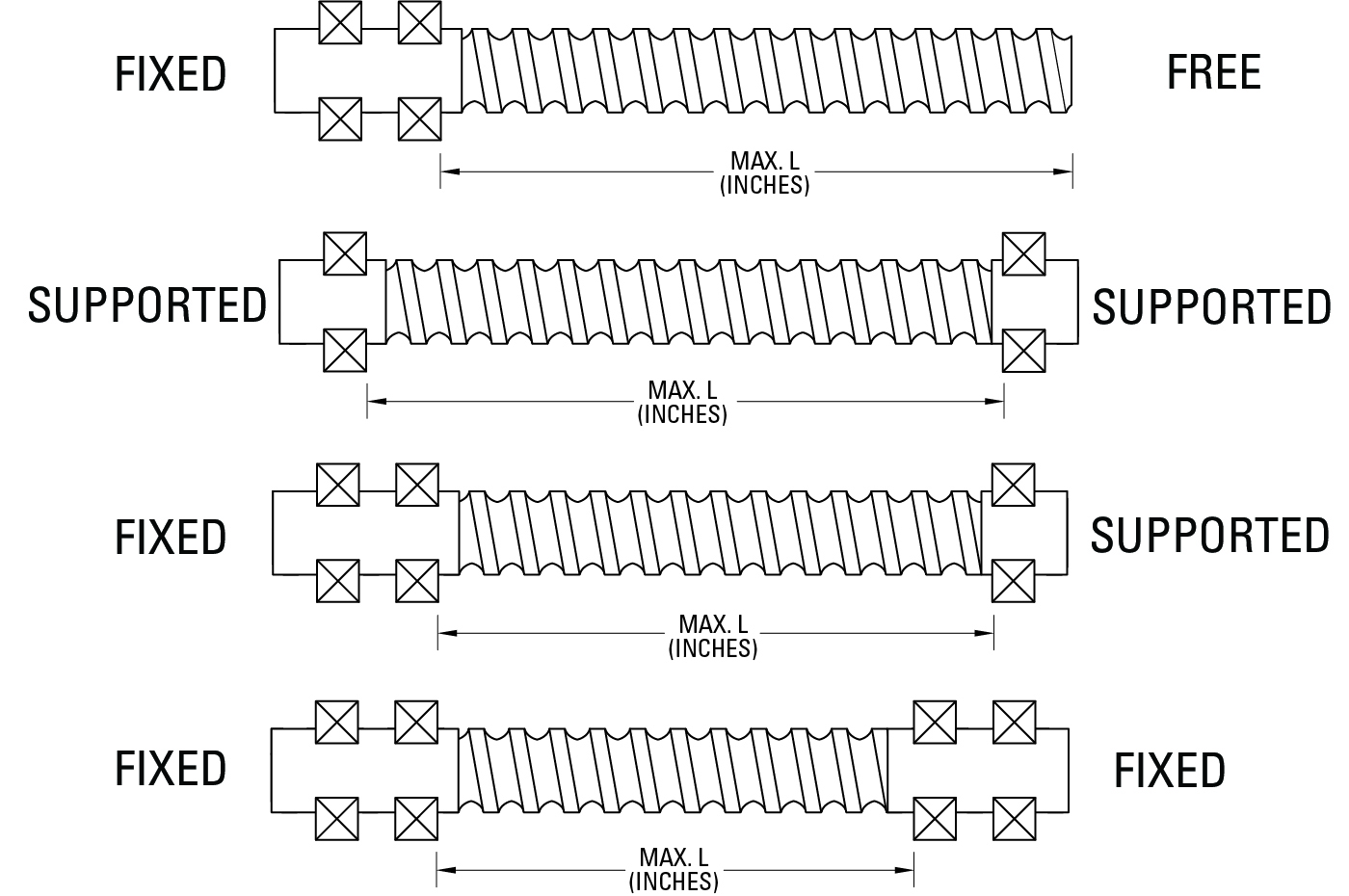

Ball screws are mounted in either supported or fixed configurations. A supported end holds the ball screw at one focal point and does not resist bending moments. A supported end is generally easier to align and install than a fixed one, so installation costs are typically lower. A fixed end resists bending moment loads because it is typically based on two bearings spaced sufficiently so the ball screw remains perpendicular to the planes of the rotary bearings. The fixed offers greater column strength and higher critical speed. The image below illustrates four fixity options.

The assembly can be fixed at both ends, fixed at only one end and supported on the other, supported at both ends, or fixed at one end and free at the other.

Ball screw assemblies are not all alike. Whether it be metric ball screws, inch ball screws or miniature ball screws, key differences affect their performance and extend their lives. These include:

- Design. Through extensive research and evaluations, Thomson engineers have been able to develop a comprehensive ball screw offering that delivers optimal solutions for countless applications. Available in a full range of diameters, leads and ball nut configurations, in either pre-loaded or non-pre-loaded types, and all in industry standard envelopes, our ball screws provide dependable accuracy and repeatability at an economical price.

- Quality. With a vast background in countless applications, Thomson is uniquely positioned to provide the highest levels of quality across our full line of ball screw assemblies. Our fully equipped engineering laboratory performs qualification testing for mechanical performance, environmental effects and structural integrity. Your rotating ball screw nut assembly is inspected every step of the way to ensure top quality and performance.

- Materials. The materials used to manufacture ball screw assemblies are critical to their performance. Our in-house metallurgists control and verify that the materials used are of the highest quality. They can also select and recommend materials best suited to your particular application.

- Manufacturing. Thomson maintains the most modern and complete ball screw manufacturing facilities in the industry. In-house manufacturing capabilities include our proprietary heat treating and plating processes. Expert manufacturing using the most modern equipment available provides ball screw assemblies that set the standards for performance, precision and travel life.

- Application Support. Working with Thomson is like having your own staff of ball screw design engineers able to address application concerns and recommend solutions. Thomson field sales and applications engineering personnel have more ball screw expertise than any other group in the industry. They are skilled at evaluating your requirements and designing assemblies that fit your needs.

Thomson 볼 스크류의 장점

동영상: Thomson 스마트 엑추에이터: 스마트 도구로 스마트 기계 설계하기

동영상: 선형 운동 설계의 부하 능력, 수명 및 소형화를 최대한 끌어 올리기

새로운 응용 분야를 설계할 때는 제품 성능과 수명, 비용을 주의 깊게 분석해야 합니다. 큰 부하를 감당해야 할 때는 더욱 그렇습니다. 향후 선형 운동 응용 분야에서 표준 볼 스크류 대신 고부하 볼 스크류를 고려해야 하는 이유를 알아보십시오.

강연자: 독일 Thomson Neff Industries의 스크류, 스크류 잭 및 LB&G 제품군 전문가 Markus Brändle

동영상: 기술 팁: 미터 시리즈 볼 너트에 볼 베어링을 장착하는 방법

베어링을 버튼 리턴 볼 너트에 다시 장착하는 방법 버튼 리턴 볼 너트 대부분이 미터 볼 너트입니다. 하지만 튜브 리턴 볼 너트에도 이 기술을 사용할 수 있습니다.

동영상: 응용 분야에 적합한 볼 스크류를 선택하기 위해 고려하고 계산해야 하는 항목

수천 가지 제품 중에 자신의 선형 운동 응용 분야에 가장 적합한 크기의 볼 스크류 솔루션을 빠르고 확실하게 선택하는 벙법이 궁금하십니까?

동영상: 기술 팁: 볼 너트를 볼 스크류로 이동시키는 방법

목재에서 볼 너트를 스크류에 설치하는 방법

기술 문서

-

인치 볼 스크류와 미터 볼 스크류: 올바른 질문을 하고 계십니까?

인치 볼 스크류와 미터 볼 스크류를 모두 사용할 수 있기 때문에 사양을 작성하는 과정에서 측정 단위를 기반으로 제품군을 선택하는 설계자가 있습니다. 이런 결정을 내리면 응용 분야에 이상적인 제품이 제외될 수 있으며 시간과 노동력, 비용이 크게 늘어날 수 있습니다. 이 글은 제품 이름이 아니라 성능을 위주로 제품 크기와 종류를 선택하면 더 효율적인 선형 운동 설계를 달성할 수 있음을 설명합니다.

추가 정보 -

고부하 볼 스크류 - 고부하 밀도로 운동을 제어하는 솔루션

이제까지 제한된 크기로 큰 부하를 감당해야 할 때는 롤러 스크류가 유일한 선택지라고 생각했습니다. 하지만 실제적으로 볼 스크류 기술이 발전함에 따라 볼 스크류로도 큰 부하를 감당할 수 있게 되었습니다. 고부하 볼 스크류는 비슷한 성능의 롤러 스크류보다 값이 50% 이상 저렴하므로 이는 중요한 문제입니다.

추가 정보 -

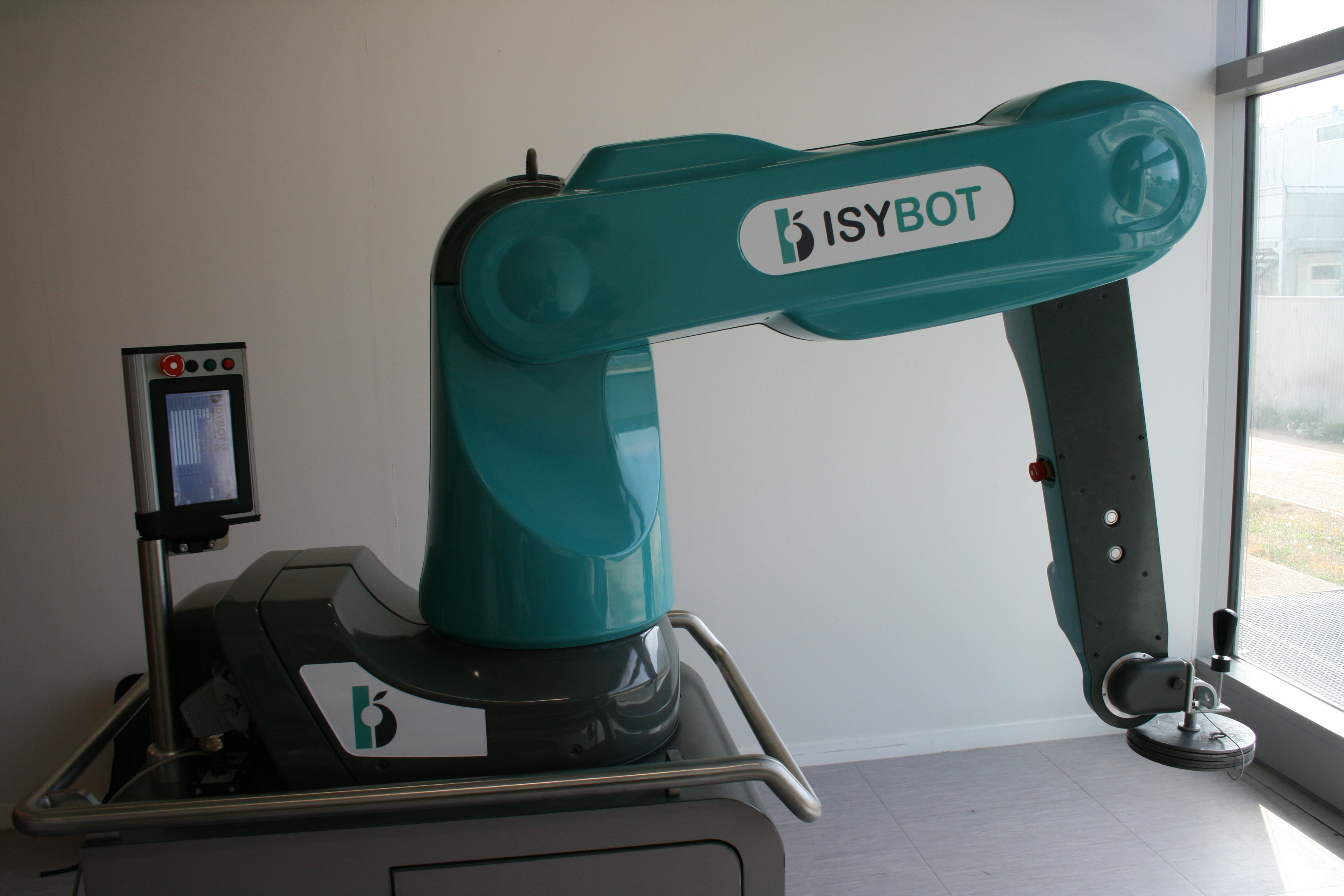

볼 스크류 – 코봇이 안전하고 효율적으로 작동하기 위한 해결책

물건을 끊임없이 들어 올리면서도 사람의 손길이 필요한 대규모 생산 응용 분야에서 사용하는 코봇(인간과의 협업을 위해 만들어진 로봇)이 인기를 얻고 있습니다. 한 프랑스 코봇 제작 업체에서 기어 대신 볼 스크류와 케이블 엑추에이터를 사용하는 코봇을 제작해 코봇의 효율성과 안전성을 한 단계 끌어올렸습니다.

추가 정보

브로셔

| Flanged Metric Precision Rolled Ball Screws (16 - 50 mm) | 756 KB | |

| Ball Screw Refurbishment Service in Europe | 693 KB | |

| Ball Screw Refurbishment Service in Europe | 694 KB | |

| 고하중 볼 스크류 | 395 KB | |

| 고하중 볼 스크류 | 370 KB | |

| 고하중 볼 스크류 | 391 KB | |

| Metric Precision Ball Screws (Made in Germany) | 1053 KB | |

| Metric Precision Ball Screws (Made in Germany) | 1062 KB | |

| 미니어처 미터법 볼 스크류는 | 625 KB | |

| 미니어처 미터법 볼 스크류는 | 655 KB | |

| 미니어처 미터법 볼 스크류는 | 668 KB | |

| Miniature Components and Systems | 6871 KB | |

| Miniature Components and Systems | 6871 KB | |

| Miniature Components and Systems | 6862 KB | |

| Miniature Components and Systems | 6862 KB | |

| Miniature Components and Systems | 1603 KB |

카탈로그

설명서

Technical Articles

| Thomson High-Load Ball Scews Provide Maximum Load Capacity and Longer Life in a Compact Envelope | 2019-02-04 |

Certifications

| 볼 스크류 어셈블리 | |||

| 볼 스크류 어셈블리 - 인치 |  |

— | — |

| 볼 스크류 어셈블리 - 미터(북미) |  |

— | — |

| 볼 스크류 어셈블리 - 미터(유럽) |  |

— | — |

| 볼 너트 | |||

| 플랜지 볼 너트 - 인치 |  |

— | — |

| 플랜지 볼 너트 - 미터 |  |

— | — |

| 나사산 볼 너트 - 인치 |  |

— | — |

| 나사산 볼 너트 - 미터 |  |

— | — |

| 원통형 볼 너트 - 미터 |  |

— | — |

| 엔드 서포트 | |||

| 볼 스크류 엔드 서포트 - 인치 |  |

— | — |

| 볼 스크류 엔드 서포트 - 미터 |  |

— | — |

| 스크류 | |||

| 정밀 롤형 볼 스크류 - 인치 |  |

— | — |

| 정밀 롤형 볼 스크류 - 미터 |  |

— | — |

| 액세서리 | |||

| 볼 스크류 및 플랜지 |  |

— | — |

| 볼 스크류 및 와이퍼 |  |

— | — |

To provide better service to you on our websites, we and our service providers use cookies to collect your personal data when you browse. For information about our use of cookies and how to decline them or turn them off please read our cookie policy [available here].