Choose Your Login Account

Thomson currently has two account systems - one for the website and CAD model downloads, and one for e-commerce. We understand that two logins is an inconvenience and are working to consolidate our systems into one login process. Until we’re able to consolidate the two logins, please follow these guidelines:

- Download CAD models

- Save and retrieve projects in LinearMotioneering® and MicronMotioneering® tools

- Access Distributor Extranet and all related resources

- Order directly from Thomson online (North America only)

- Authorized Thomson Distributors can view and order from quotes online (Global)

- View the shopping cart and look up prior direct orders

Genel özet

Why Choose Ball Screw Assemblies?

Ball screw assemblies provide an excellent method for translating rotational motion to linear motion for many applications, including those where high loads and close tolerances are required. To apply the correct type of ball screw and nut assembly in a particular application, the design engineer must consider the advantages and capabilities of each. Selecting the right technology can reduce design complexity, improve performance and reduce the overall cost of the assembly.

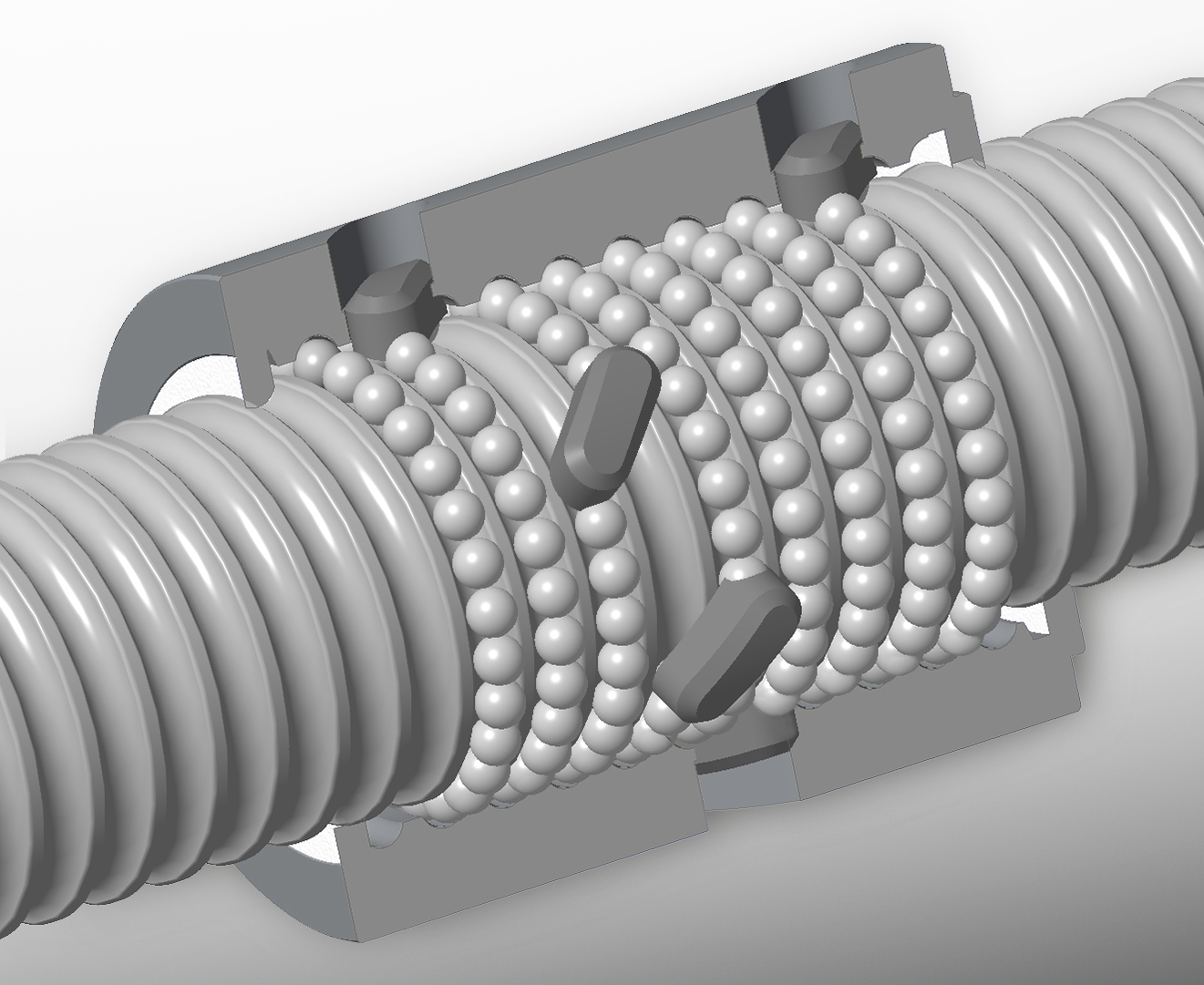

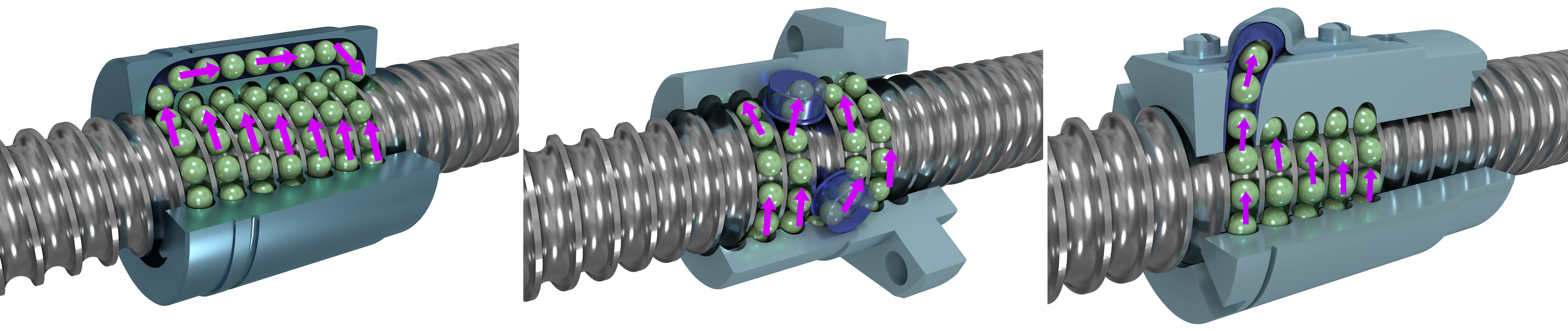

This image compares the three types of ball return systems (from left to right): internal, button and external.

Mounting Options

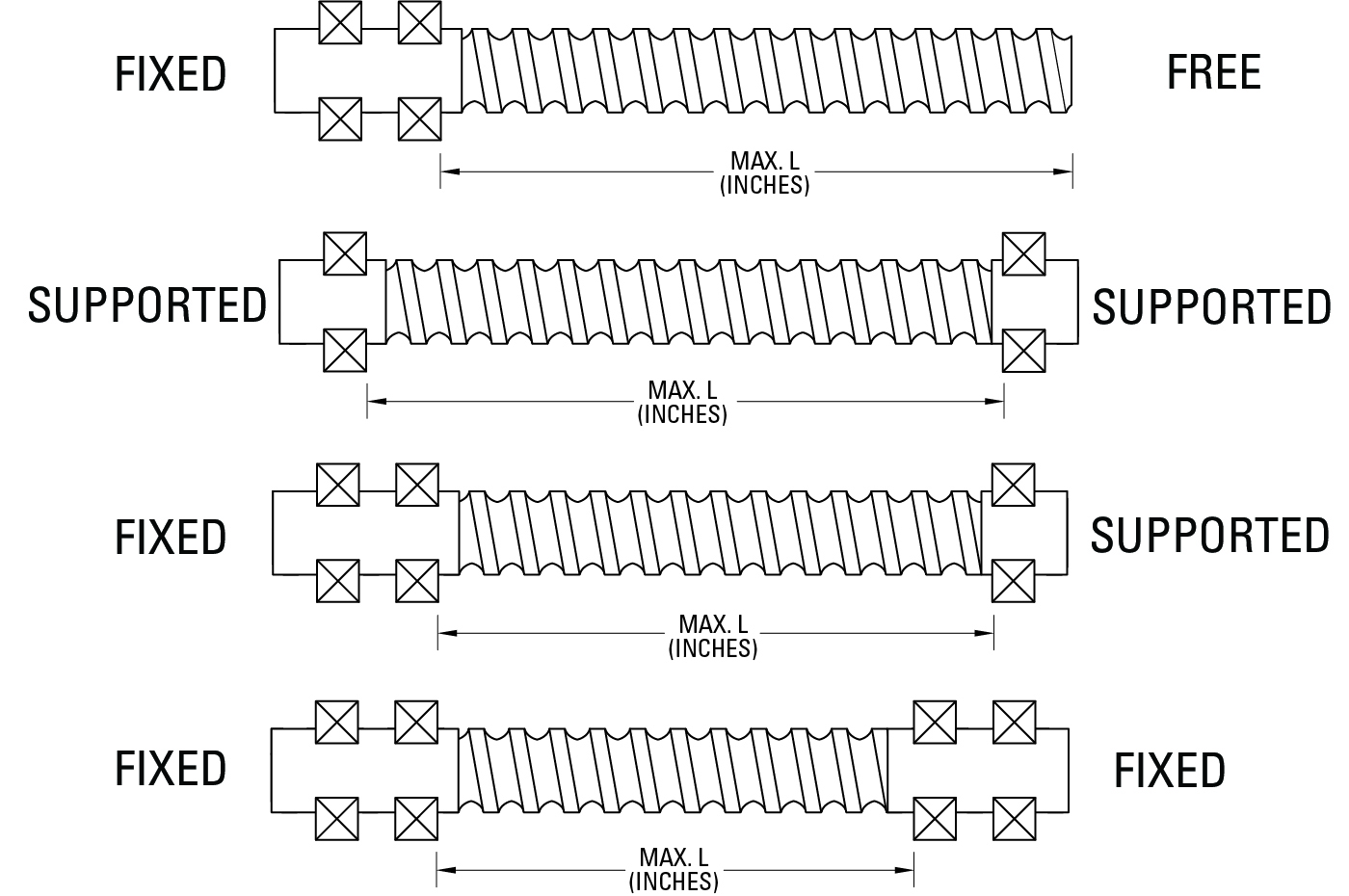

Ball screws are mounted in either supported or fixed configurations. A supported end holds the ball screw at one focal point and does not resist bending moments. A supported end is generally easier to align and install than a fixed one, so installation costs are typically lower. A fixed end resists bending moment loads because it is typically based on two bearings spaced sufficiently so the ball screw remains perpendicular to the planes of the rotary bearings. The fixed offers greater column strength and higher critical speed. The image below illustrates four fixity options.

The assembly can be fixed at both ends, fixed at only one end and supported on the other, supported at both ends, or fixed at one end and free at the other.

Ball screw assemblies are not all alike. Whether it be metric ball screws, inch ball screws or miniature ball screws, key differences affect their performance and extend their lives. These include:

- Design. Through extensive research and evaluations, Thomson engineers have been able to develop a comprehensive ball screw offering that delivers optimal solutions for countless applications. Available in a full range of diameters, leads and ball nut configurations, in either pre-loaded or non-pre-loaded types, and all in industry standard envelopes, our ball screws provide dependable accuracy and repeatability at an economical price.

- Quality. With a vast background in countless applications, Thomson is uniquely positioned to provide the highest levels of quality across our full line of ball screw assemblies. Our fully equipped engineering laboratory performs qualification testing for mechanical performance, environmental effects and structural integrity. Your rotating ball screw nut assembly is inspected every step of the way to ensure top quality and performance.

- Materials. The materials used to manufacture ball screw assemblies are critical to their performance. Our in-house metallurgists control and verify that the materials used are of the highest quality. They can also select and recommend materials best suited to your particular application.

- Manufacturing. Thomson maintains the most modern and complete ball screw manufacturing facilities in the industry. In-house manufacturing capabilities include our proprietary heat treating and plating processes. Expert manufacturing using the most modern equipment available provides ball screw assemblies that set the standards for performance, precision and travel life.

- Application Support. Working with Thomson is like having your own staff of ball screw design engineers able to address application concerns and recommend solutions. Thomson field sales and applications engineering personnel have more ball screw expertise than any other group in the industry. They are skilled at evaluating your requirements and designing assemblies that fit your needs.

Thomson Bilyalı Vidaları Sizin İçin Ne Yapabilir?

VİDEO: Thomson Akıllı Aktüatörleri: Akıllı Aletlerle Akıllı Makineler Tasarlama

VİDEO: Lineer Hareket Tasarımlarınızın Yük Kapasitesini, Yaşam Döngüsünü ve Kompaktlığını En Üst Düzeye Çıkarın

Herhangi bir yeni uygulama, ürün performansı, ömrü ve maliyetinin dikkatli bir şekilde analizini gerektirir. Özellikle daha büyük yükleri üstlenenler. Bir sonraki lineer hareket uygulamanız için neden standart bilyalı vida yerine yüksek yüklü bilyalı vidayı düşünmeniz gerektiğini öğrenin.Sunucu: Markus Brändle, Ürün Hattı Uzmanı - Vidalar, Vidalı Krikolar ve LB&G Thomson Neff Industries, Almanya

VİDEO: Teknik İpuçları: Bilyalı Yatakların Metrik Serisi bir Bilyalı Somuna Yüklenmesi

Yataklar bir düğme geri dönüşlü bilyalı somuna nasıl yeniden yüklenir. Genellikle Metrik bilyalı somunlar, düğme geri dönüşlü bilyalı somunlardır. Ancak bu teknik, boru dönüşlü bilyalı somunlarda da kullanılabilir.

VİDEO: Uygulamanız İçin Doğru Bilyalı Vida Seçimi için Dikkat Edilmesi Gerekenler ve Hesaplamalar

Binlerce olası seçenek arasından, lineer hareket uygulamanız için en uygun vidalı mil çözümünü nasıl hızlı ve güvenli bir şekilde boyutlandırabilir ve seçebilirsiniz?

VİDEO: Teknik İpuçları: Bilyalı Somun Bilyalı Vidaya Nasıl Aktarılır

Bir milden bir vidaya bir bilyalı somun nasıl takılır.

Teknik Makaleler

-

İnç ve Metrik Bilyalı Vidalar: Doğru Soruları mı Soruyorsunuz?

Bilyalı vidalar hem inç hem de metrik boyutlarda mevcut olduğundan, tasarımcılar bazen ölçü birimine dayalı bir ürün ailesi seçerek spesifikasyon sürecine başlarlar. Bu karar, uygulama için ideal ürünü zamanından önce dışlayabilir ve önemli zaman, işçilik ve masraf kayıplarına yol açabilir. Bu makale, ürün adları yerine performansa odaklanan boyutlandırma ve seçim sorularının nasıl daha verimli lineer hareket tasarımlarına yol açabileceğini açıklamaktadır.

Daha fazla bilgi -

Yüksek Yük Bilyalı Vidaları - Daha Yüksek Yük Yoğunluğu Olan Hareket Kontrol Çözümü

Makaralı vidalar, boyutun bir kısıtlama olduğu durumlarda büyük yükleri taşımak için tercih edilen tek teknoloji olarak tanıtılmıştır. Ancak gerçekte, bilyalı vida teknolojisindeki gelişmeler artık yüksek yüklü uygulamaları da destekleme özelliğini mümkün kılmıştır. Bu önemlidir, çünkü yüksek yüklü bir bilyalı vida, tipik olarak eşdeğer performans noktalarında karşılaştırılabilir bir makaralı vidanın maliyetinin yarısından daha azdır.

Daha fazla bilgi -

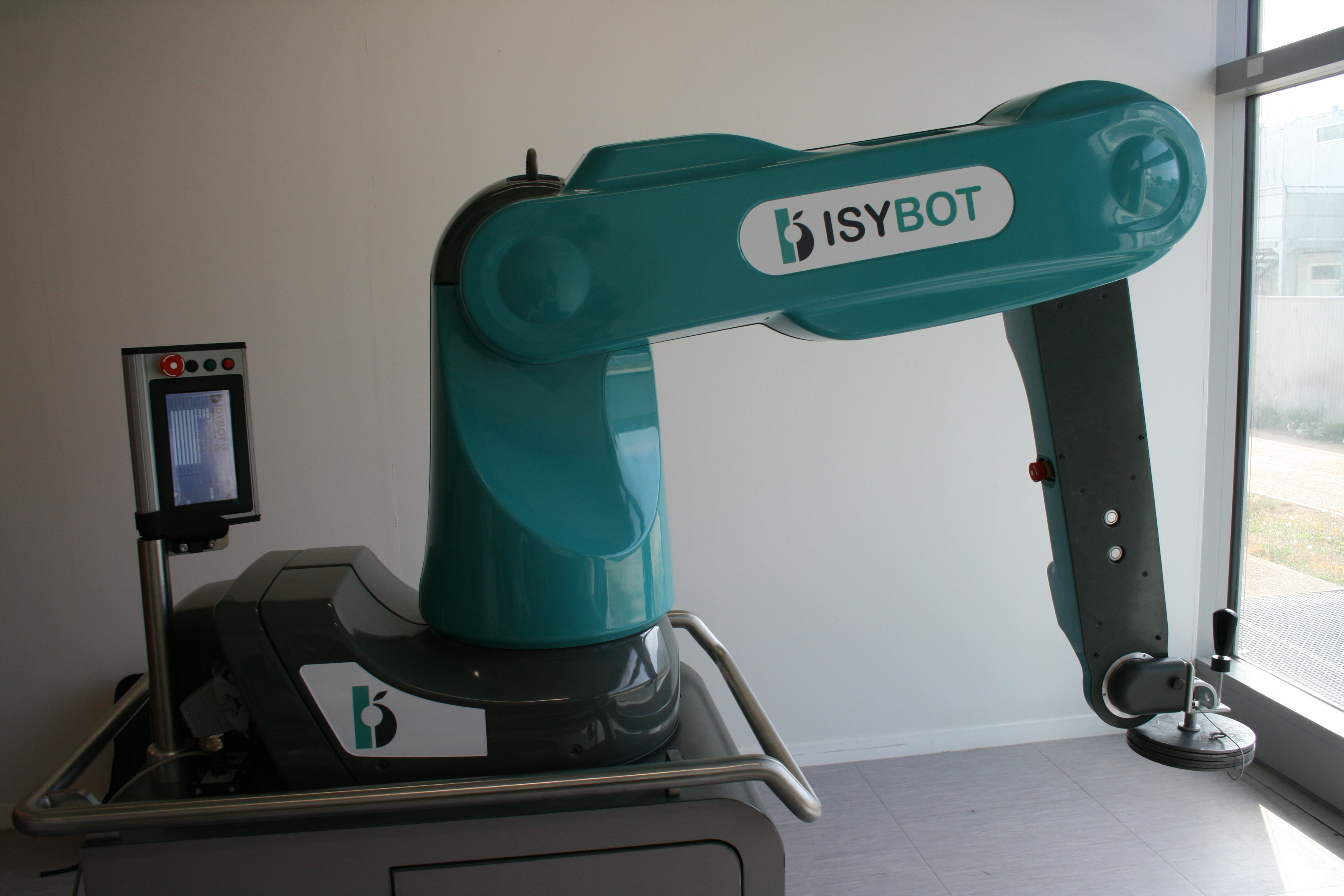

Bilyalı Vidalar - Cobot'lar için Güvenli ve Verimli Harekete Bir Yanıt

Sürekli kaldırma işlemlerini içeren ancak yine de insan dokunuşu gerektiren büyük ölçekli üretim uygulamalarında kullanılan işbirliği robotları (cobot'lar) popülerlik kazanmaktadır. Bir Fransız cobot üreticisi, dişliler yerine bilyalı vida ve kablo aktüatörleri kullanan ve cobot verimliliği ve güvenliği için yeni bir ölçüt belirleyen bir çözüm geliştirdi.

Daha fazla bilgi

Broşürler

Kataloglar

Kılavuzlar

Technical Articles

| Thomson High-Load Ball Scews Provide Maximum Load Capacity and Longer Life in a Compact Envelope | 2019-02-04 |

Certifications

| BİLYALI VİDA TERTİBATLARI | |||

| Bilyalı Vida Tertibatları - İnç |  |

— | — |

| Bilyalı Vida Tertibatları - Metrik (Kuzey Amerika) |  |

— | — |

| Bilyalı Vida Tertibatları - Metrik (Avrupa) |  |

— | — |

| BİLYALI SOMUNLAR | |||

| Flanşlı Bilyalı Somunlar - İnç |  |

— | — |

| Flanşlı Bilyalı Somunlar - Metrik |  |

— | — |

| Dişli Bilyalı Somunlar - İnç |  |

— | — |

| Dişli Bilyalı Somunlar - Metrik |  |

— | — |

| Silindirik Bilyalı Somunlar - Metrik |  |

— | — |

| UÇ DESTEKLERİ | |||

| Bilyalı Vida Uç Destekleri - İnç |  |

— | — |

| Bilyalı Vida Uç Destekleri - Metrik |  |

— | — |

| VİDALAR | |||

| Hassas Yuvarlanmış Bilyalı Vidalar - İnç |  |

— | — |

| Hassas Yuvarlanmış Bilyalı Vidalar - Metrik |  |

— | — |

| AKSESUARLAR | |||

| Bilyalı Vida Flanşları |  |

— | — |

| Bilyalı Vida Silecekleri |  |

— | — |

To provide better service to you on our websites, we and our service providers use cookies to collect your personal data when you browse. For information about our use of cookies and how to decline them or turn them off please read our cookie policy [available here].