Choose Your Login Account

Thomson currently has two account systems - one for the website and CAD model downloads, and one for e-commerce. We understand that two logins is an inconvenience and are working to consolidate our systems into one login process. Until we’re able to consolidate the two logins, please follow these guidelines:

- Download CAD models

- Save and retrieve projects in LinearMotioneering® and MicronMotioneering® tools

- Access Distributor Extranet and all related resources

- Order directly from Thomson online (North America only)

- Authorized Thomson Distributors can view and order from quotes online (Global)

- View the shopping cart and look up prior direct orders

Customer Service Chat (ONLINE) Customer Service Chat (OFFLINE)

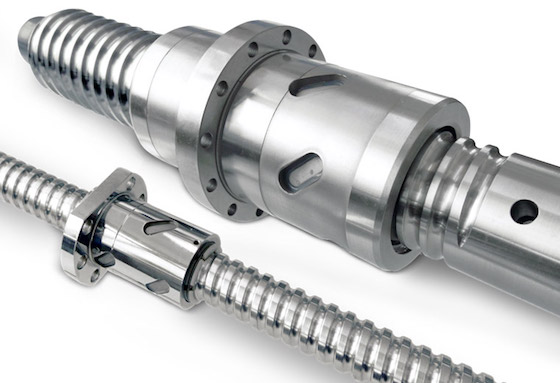

Ball Screws

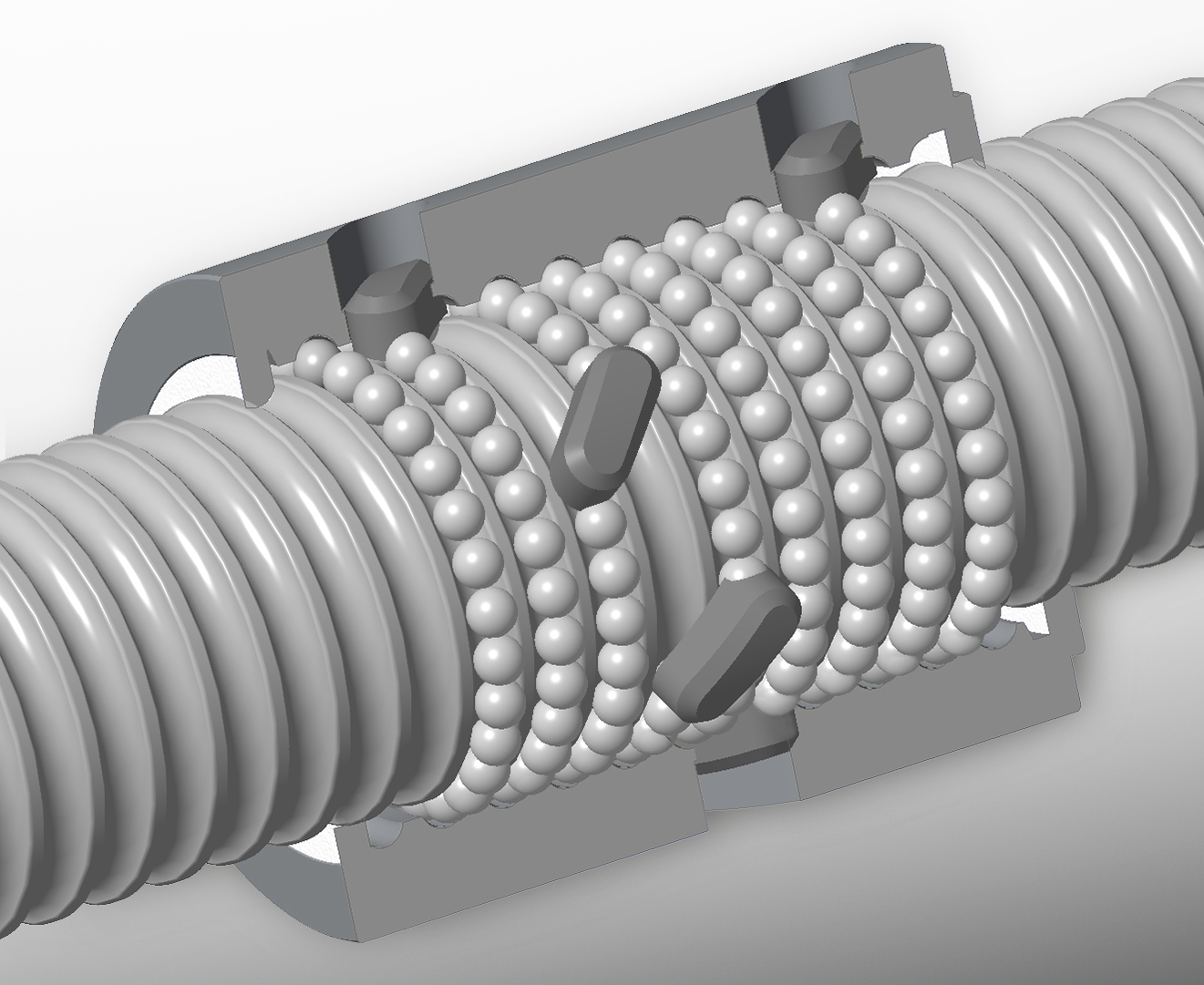

The ball screw drive is an assembly that converts rotary motion to linear motion (or vice versa). It consists of a ball screw and a ball nut packaged as an assembly with recirculating balls. The interface between the ball screw and the nut is made by balls which roll in matching ball forms. With rolling elements, the ball screw drive has a low friction coefficient (typically up to 98%). The forces transmitted are distributed over a large number of balls, giving a low relative load per ball comparatively.

Standard Ball Screws

Precision Rolled Inch Ball Screws

Miniature Metric Precision Ball Screws

Precision Rolled Metric Ball Screws

Precision Plus Ground Metric Ball Screws

Bearing Supports

High-Load Ball Screws

Installation, Maintenance, Lubrication, and Repair

Ideal for high-precision, high-load applications, metric and inch ball screws are manufactured to the highest standards to translate rotational motion to linear motion with minimal internal friction.

Why Thomson Ball Screws?

Not all precision ball screws are created equal. At Thomson, our careful attention to design, quality, materials, manufacturing and application support has set us apart from the competition and created an ideal recipe for success that has lasted for decades.

Customization Options

When standard Thomson ball screws don’t meet your exact specification requirements, our engineering experts can help customize a solution for your application. Whether it’s one or a large quantity, a simple component modification or complex assembly, our custom capabilities can meet your needs and improve your machine’s performance.

Where Can You Get Started?

Thomson provides extensive online resources to help you no matter where you may be in the purchase decision process:

What Can Thomson Ball Screws Do For You?

VIDEO: Ball Screws: Design and Installation

This video provides an overview of the anatomy and installation of ball screws. It covers the function of ball screws in application design as well as the components of a ball screw assembly and of a ball nut. Also included is a demonstration of the installation of a ball nut onto a screw and the ball bearing insertion process in the event that some bearings fall out during installation.

VIDEO: Maximize Load Capacity, Lifecycle and Compactness of Your Linear Motion Designs

Any new application requires careful analysis of product performance, life and cost. Especially those that take on larger loads. Learn why you should be considering a high-load ball screw over standard ball screws for your next linear motion application.

Presenter: Markus Brändle, Product Line Specialist – Screws, Screw Jacks and LB&G Thomson Neff Industries, Germany

VIDEO: Tech Tips: How to Load Ball Bearings into a Metric Series Ball Nut

How to reload the bearings into a button return ball nut. Often Metric ball nuts are button return ball nuts. But this technique can also be used on tube return ball nuts.

VIDEO: Considerations and Calculations for Choosing the Right Ball Screw for Your Application

From all the thousands of possible choices, how can you quickly and confidently size and select the optimal ball screw solution for your linear motion application?

VIDEO: Tech Tips: How to Transfer a Ball Nut to a Ball Screw

How to install a ball nut onto a screw from an arbor.

Technical Articles

-

Inch vs. Metric Ball Screws: Are You Asking the Right Questions?

Because ball screws are available in both inch and metric dimensions, designers sometimes begin the specification process by selecting a product family based on the unit of measure. This decision may prematurely exclude the ideal product for the application and lead to significant losses in time, labor and expense. This article explains how sizing and selection questions centered on performance – instead of product monikers – can lead to more efficient linear motion designs.

Learn More -

High Load Ball Screws - The Motion Control Solution with Higher Load Density

Roller screws have been promoted as the only technology of choice for handling large loads when size is a constraint. But in actuality, advances in ball screw technology have now enabled the capability to support high-load applications as well. This is important because a high-load ball screw is typically less than half the cost of a comparable roller screw at equivalent performance points.

Learn More -

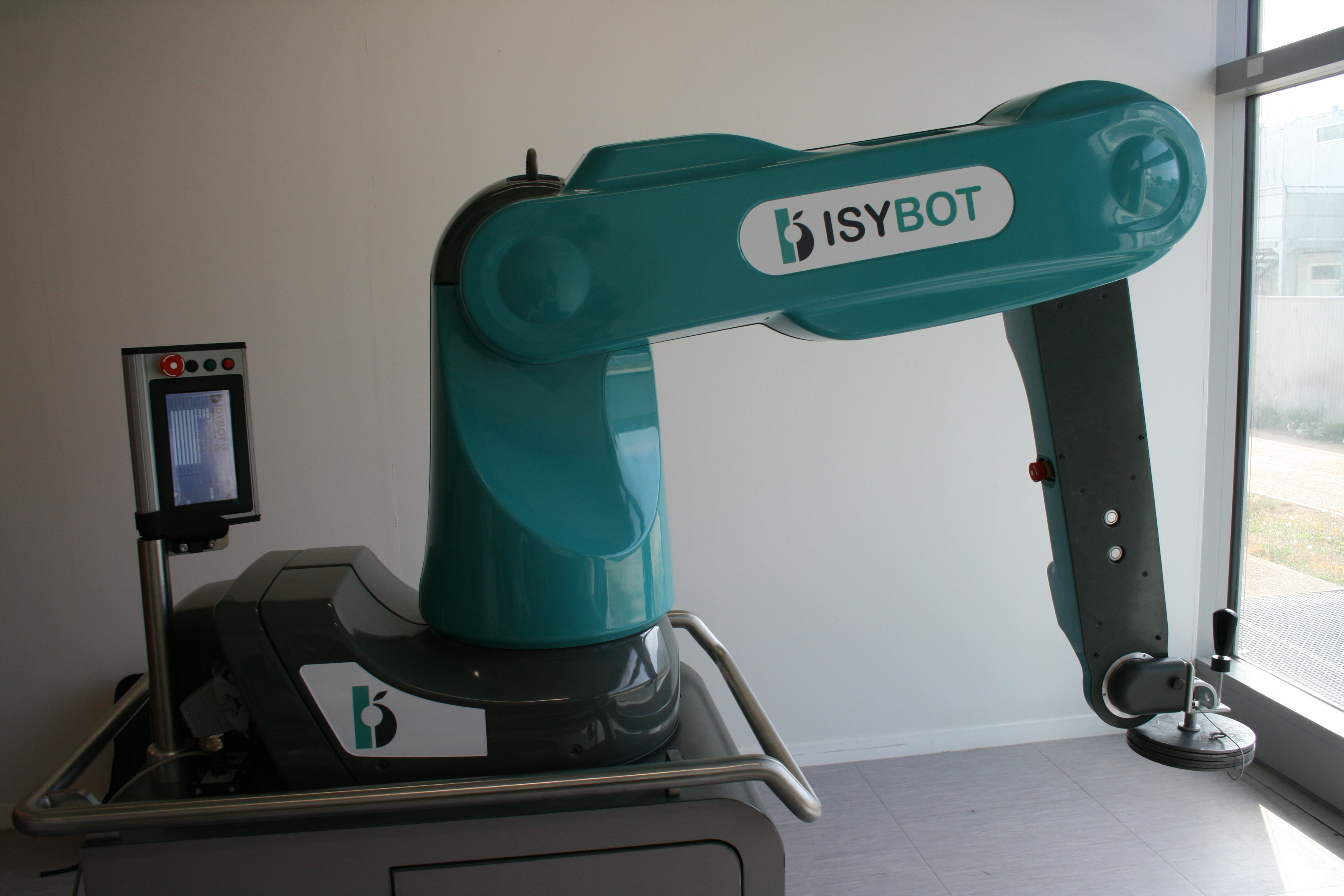

Ball Screws – An Answer to Safe and Efficient Motion for Cobots

Used in large-scale production applications that involve continuous lifting operations but still require a human touch, collaboration robots (cobots) are gaining popularity. A French cobot maker has developed a solution that uses ball screw and cable actuators instead of gears, setting a new benchmark for cobot efficiency and safety.

Learn More

Brochures

Catalogs

Manuals

Technical Articles

Press Releases

| Thomson High-Load Ball Scews Provide Maximum Load Capacity and Longer Life in a Compact Envelope | 2019-02-04 |

Certifications

| Ball Screw Assemblies | |||

| Ball Screw Assemblies - Inch |  |

— | — |

| Ball Screw Assemblies - Metric (North America) |  |

— | — |

| Ball Screw Assemblies - Metric (Europe) |  |

— | — |

| Ball Nuts | |||

| Flanged Ball Nuts - Inch |  |

— | — |

| Flanged Ball Nuts - Metric |  |

— | — |

| Threaded Ball Nuts - Inch |  |

— | — |

| Threaded Ball Nuts - Metric |  |

— | — |

| Cylindrical Ball Nuts - Metric |  |

— | — |

| End Supports | |||

| Ball Screws End Supports - Inch |  |

— | — |

| Ball Screw End Supports - Metric |  |

— | — |

| Screws | |||

| Precision Rolled Ball Screws - Inch |  |

— | — |

| Precision Rolled Ball Screws - Metric |  |

— | — |

| Accessories | |||

| Ball Screw Flanges |  |

— | — |

| Ball Screw Wipers |  |

— | — |

To provide better service to you on our websites, we and our service providers use cookies to collect your personal data when you browse. For information about our use of cookies and how to decline them or turn them off please read our cookie policy [available here].