Choose Your Login Account

Thomson currently has two account systems - one for the website and CAD model downloads, and one for e-commerce. We understand that two logins is an inconvenience and are working to consolidate our systems into one login process. Until we’re able to consolidate the two logins, please follow these guidelines:

- Download CAD models

- Save and retrieve projects in LinearMotioneering® and MicronMotioneering® tools

- Access Distributor Extranet and all related resources

- Order directly from Thomson online (North America only)

- Authorized Thomson Distributors can view and order from quotes online (Global)

- View the shopping cart and look up prior direct orders

Mechanizmy śrubowo-toczne

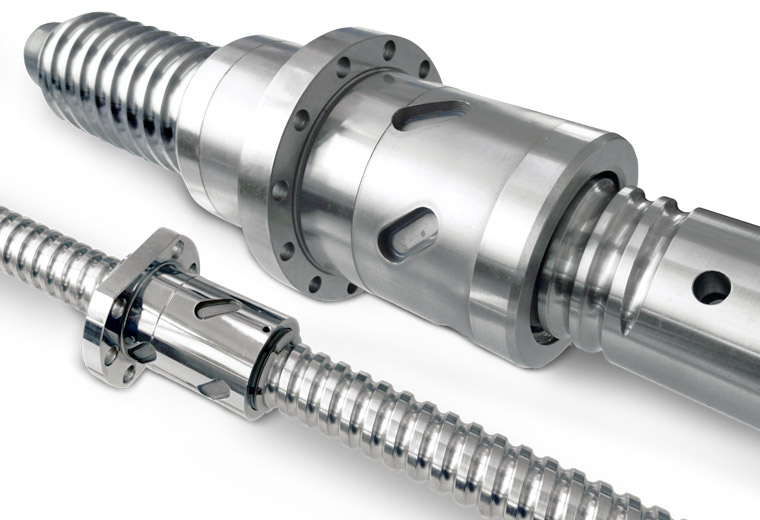

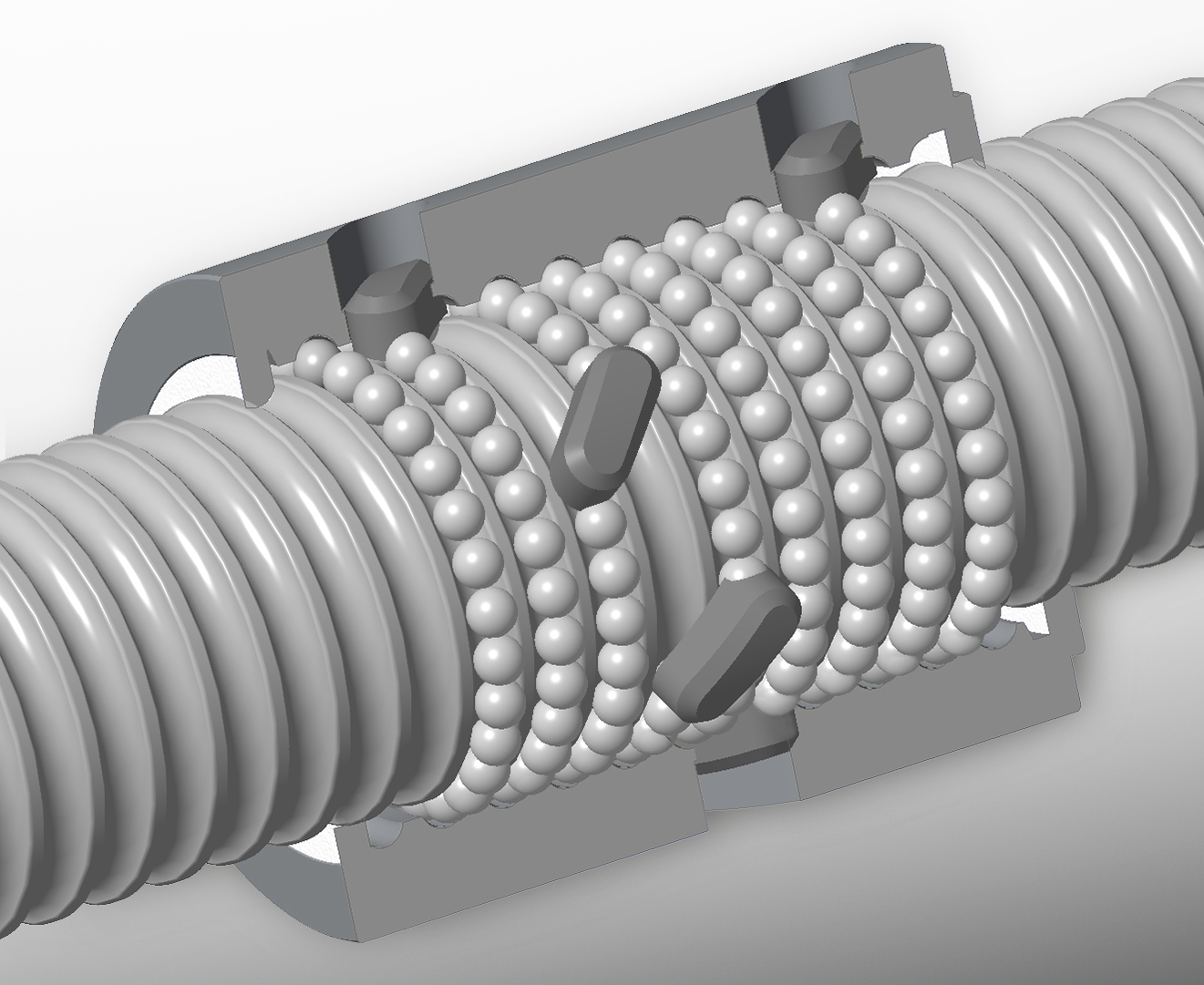

Napęd wykorzystujący mechanizm śrubowo-toczny jest zespołem przenoszącym ruch obrotowy na liniowy (lub odwrotnie). Napęd składa się ze mechanizmu śrubowo-tocznego i nakrętki kulowej umiejszczonych w jednym zespole wraz z nawrotnymi łożyskami kulkowymi. Połączenie pomiędzy mechanizmem śrubowo-tocznym i nakrętką zapewniają odpowiednie obiegi łożysk kulkowych. Dzięki elementom tocznym napęd z mechanizmem śrubowo-tocznym charakteryzuje się bardzo niskim współczynnikiem tarcia i ponad 90% wydajnością. Wytwarzane siły rozdzielane są na wiele kulek łożyskowych, co gwarantuje niskie obciążenia każdej kulki.

Standardowe kulowe śruby pociągowe

Precyzyjne walcowane mechanizmy śrubowo-toczne

Miniaturowe metryczne śruby kulowe

Precyzyjne walcowane śruby metryczne z nakrętką kulkową

Precyzyjne szlifowane mechanizmy śrubowo-toczne

Wsporniki łożysk - metryczne

Śruby kulowe do dużych obciążeń

Instalacja, konserwacja, smarowanie i naprawy

Kulowe śruby pociągowe na indywidualne zamówienie

Zoptymalizuj realizowany projekt z użyciem rozwiązania kulowej śruby pociągowej przygotowanego na indywidualne zamówienie.

Idealne do zastosowań o wysokiej precyzji i dużym obciążeniu, metryczne i imperialne kulowe śruby pociągowe produkowane są zgodnie z najwyższymi standardami w celu przełożenia ruchu obrotowego na ruch liniowy z minimalnym tarciem wewnętrznym.

Dlaczego warto wybrać kulowe śruby pociągowe firmy Thomson?

Nie wszystkie precyzyjne kulowe śruby pociągowe tworzone są jednakowo. W firmie Thomson staranna uwaga poświęcana projektowaniu, jakości, materiałom, produkcji i wsparciu w zakresie stosowania odróżniła nas od konkurencji i okazała się idealnym przepisem na sukces, który trwa od dziesięcioleci.

Quando os parafusos de esferas padrão da Thomson não atendem às suas especificações exatas, nossos especialistas em engenharia podem ajudar a personalizar uma solução para a sua aplicação. Seja para um item ou uma grande quantidade, uma modificação simples de um componente ou uma montagem complexa, nossos recursos personalizados podem atender às suas necessidades e melhorar o desempenho da sua máquina.

Od czego zacząć?

Firma Thomson udostępnia w internecie wiele materiałów, które pomagają w podjęciu decyzji na każdym etapie procesu zakupowego:

- Zalety kulowych śrub pociągowych >

- Linear MOTIONEERING®: narzędzie doboru rozmiaru i rodzaju śrub z nakrętką kulkową i śrub pociągowych >

- Prowadnice wieloklinowe toczne >

Jak mogę wykorzystać kulowe śruby pociągowe firmy Thomson?

FILM: Inteligentne siłowniki Thomson: projektowanie inteligentnych maszyn za pomocą inteligentnych narzędzi

VIDEO: Maximize Load Capacity, Lifecycle and Compactness of Your Linear Motion Designs

Any new application requires careful analysis of product performance, life and cost. Especially those that take on larger loads. Learn why you should be considering a high-load ball screw over standard ball screws for your next linear motion application.

Presenter: Markus Brändle, Product Line Specialist – Screws, Screw Jacks and LB&G Thomson Neff Industries, Germany

FILM: Wskazówki techniczne: jak załadować łożyska kulkowe do nakrętki kulowej serii metrycznej

Jak ponownie włożyć łożyska do nakrętki kulowej z powrotem przy użyciu przycisku? Często metryczne nakrętki kulowe są nakrętkami kulowymi z powrotem przy użyciu przycisku. Technika ta może być również stosowana do nakrętek z powrotem rurkowym.

FILM: Rozważania i obliczenia dotyczące wyboru właściwej kulowej śruby pociągowej do danego zastosowania

W jaki sposób spośród tysięcy możliwych opcji można szybko i pewnie zwymiarować i wybrać optymalne rozwiązanie kulowej śruby pociągowej do danego zastosowania ruchu liniowego?

FILM: Wskazówki techniczne: jak przenieść nakrętkę kulową na kulową śrubę pociągową

Jak zamontować nakrętkę kulową na śrubie od strony trzpienia.

Artykuły techniczne

-

Calowe czy metryczne kulowe śruby pociągowe: czy zadajesz właściwe pytania?

Ponieważ kulowe śruby pociągowe są dostępne zarówno w wymiarach calowych, jak i metrycznych, projektanci czasami rozpoczynają proces specyfikacji od wyboru rodziny produktów na podstawie jednostki miary. Taka decyzja może przedwcześnie wykluczyć idealny produkt do danego zastosowania i doprowadzić do znacznych strat czasu, pracy i kosztów. W tym artykule wyjaśniono, w jaki sposób pytania dotyczące wymiarowania i doboru skoncentrowane na wydajności — a nie na nazwach produktów — mogą prowadzić do bardziej efektywnych projektów ruchu liniowego.

Daha fazla bilgi -

Kulowe śruby pociągowe do dużych obciążeń — rozwiązanie do sterowania ruchem o większej gęstości obciążenia

Śruby rolkowe były propagowane jako jedyna technologia, którą można wybrać do przenoszenia dużych obciążeń, gdy rozmiar jest ograniczeniem.W rzeczywistości jednak postęp technologii kulowych śrub pociągowych umożliwia wykorzystanie ich również do zastosowań wymagających dużych obciążeń. Jest to istotne, ponieważ kulowa śruba pociągowa o wysokiej obciążalności jest zazwyczaj o połowę tańsza od porównywalnej śruby rolkowej o takich samych parametrach.

Daha fazla bilgi -

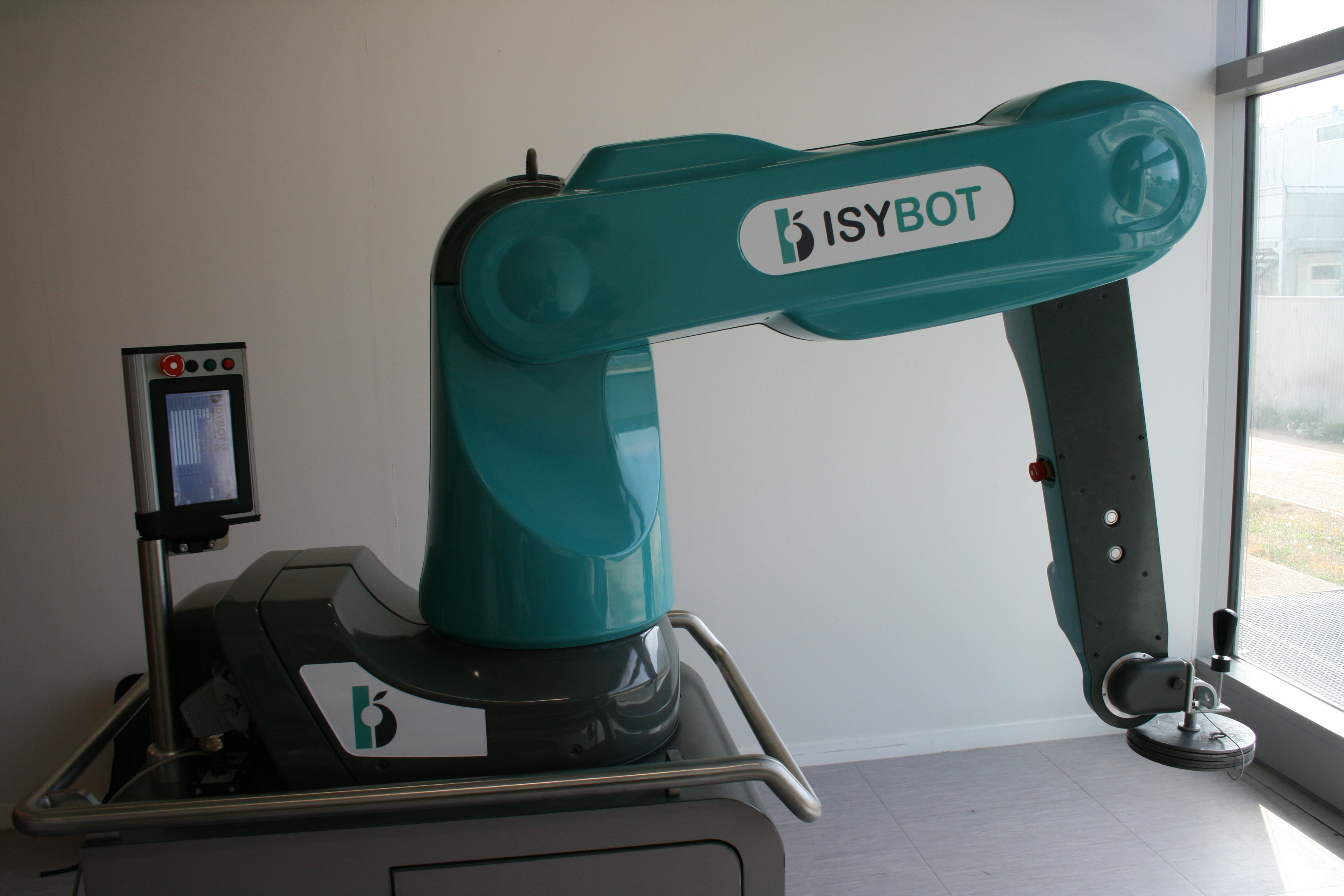

Kulowe śruby pociągowe — rozwiązanie w zakresie bezpiecznego i wydajnego ruchu kobotów

Roboty współpracujące (koboty), wykorzystywane na dużą skalę w zastosowaniach produkcyjnych, w których występują ciągłe operacje podnoszenia, ale nadal wymagany jest udział człowieka, zyskują coraz większą popularność. Francuski producent kobotów opracował rozwiązanie, które wykorzystuje kulowe śruby pociągowe i siłowniki linkowe zamiast przekładni, wyznaczając nowy standard wydajności i bezpieczeństwa kobotów.

Daha fazla bilgi

Broszury

Katalogi

Instrukcje obsługi

Technical Articles

| Thomson High-Load Ball Scews Provide Maximum Load Capacity and Longer Life in a Compact Envelope | 2019-02-04 |

Certifications

| ZESPOŁY ŚRUB KULOWYCH | |||

| Zespoły śrub kulowych – calowe |  |

— | — |

| Zespoły śrub kulowych – metryczne (Ameryka Północna) |  |

— | — |

| Zespoły śrub kulowych – metryczne (Europa) |  |

— | — |

| NAKRĘTKI KULOWE | |||

| Nakrętki kulowe kołnierzowe – calowe |  |

— | — |

| Nakrętki kulowe kołnierzowe – metryczne |  |

— | — |

| Nakrętki kulowe gwintowane – calowe |  |

— | — |

| Nakrętki kulowe gwintowane – metryczne |  |

— | — |

| Nakrętki kulowe cylindryczne – metryczne |  |

— | — |

| PODPORY KOŃCOWE | |||

| Podpory końcowe śrub kulowych – calowe |  |

— | — |

| Podpory końcowe śrub kulowych – metryczne |  |

— | — |

| ŚRUBY | |||

| Precyzyjne walcowane śruby kulowe – calowe |  |

— | — |

| Precyzyjne walcowane śruby kulowe – metryczne |  |

— | — |

| AKCESORIA | |||

| Kołnierze do śrub kulowych |  |

— | — |

| Pierścienie zgarniające do śrub kulowych |  |

— | — |

To provide better service to you on our websites, we and our service providers use cookies to collect your personal data when you browse. For information about our use of cookies and how to decline them or turn them off please read our cookie policy [available here].