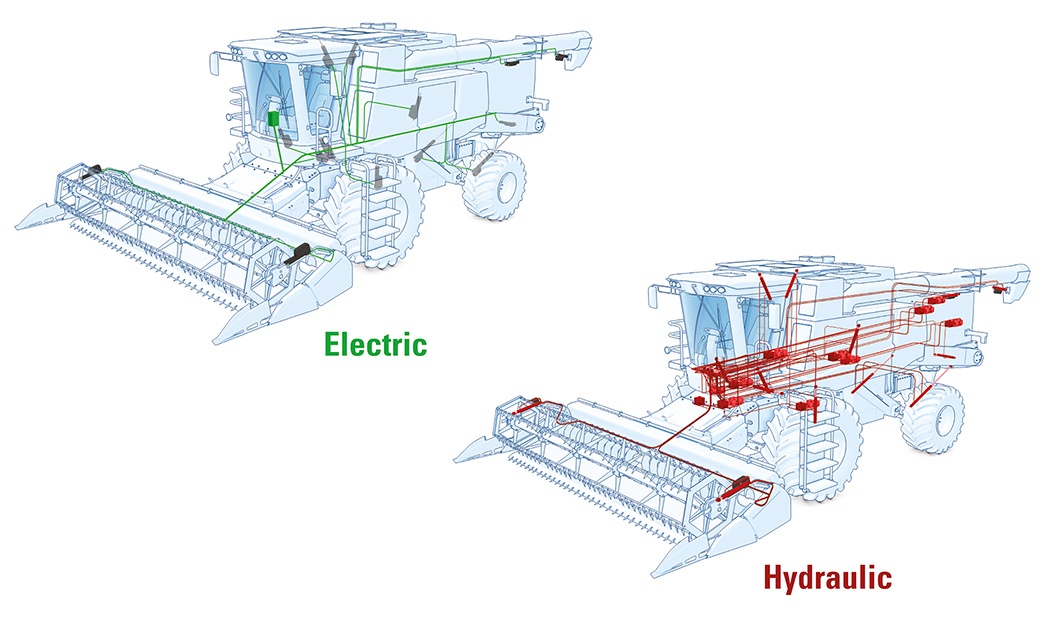

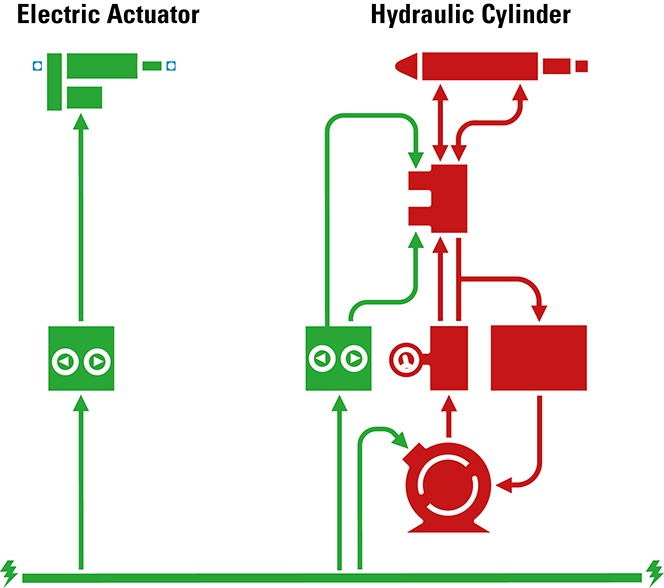

What can converting to electric do for your linear motion designs and applications? With more than 50 years’ experience in developing and installing electric linear actuators, Thomson has built a vast and diverse portfolio of solutions that has solved many issues associated with the use of hydraulic cylinders. What benefits can electrification deliver to your projects?

Clean and Simple: The Electrification of Linear Actuator Applications

The list of benefits as a result of converting from hydraulic to electric actuation is a long one, but a handful of key drivers rise to the top when it comes to making your decision:

Health and Safety

Hydraulic fluid creates safety risks for workers (personal injury), liabilities for employers and costly environmental cleanup. Converting to electric, which allows for a more compact, quiet and clean actuator design, significantly reduces the risks involved with hydraulic systems.

Controllability

With precise positioning, synchronization of multiple axes and multiple feedback options, electric actuators drive machine productivity and efficiency improvements.

Sustainability

Electric actuators use less overall power to move loads, providing unparalleled energy efficiency, while producing low noise- and leak-free operation in extreme environmental conditions.

Battery Technology

Efficiency improvements and cost reductions in battery technology can lead to value-driven, high-performance all-electric machine designs.

Talk to a Thomson expert about converting your machine designs to electric

Click Here