Design and Theory

In the event that an actuator is accidentally overloaded while it is mid stroke the actuator has some mid stroke protection. There are two main types of mid-stroke protection.

- Clutch

- Electronic load monitoring

Clutch

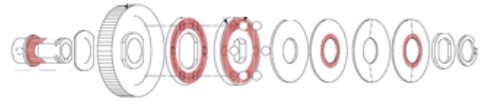

When utilizing a clutch for protection, a ball detent clutch is usually

the choice. In this style of clutch, a spring force presses the balls

into their detents. When the torque to rotate the shaft becomes too

high, the balls force themselves out of their detents against the spring

pressure. This allows the motor to turn without the shaft or screw

turning, which keeps the actuator from extending. As the clutch

continues to rotate, the balls will fall into the next set of detents.

If this continues, a ratcheting or clicking sound is heard. This should

not be allowed to continue as the clutch will quickly wear.

Electronic load monitoring

In electronic monitoring, a built-in microprocessor monitors the current

draw of the motor. If the current draw exceeds the amount required for

the load rating for the actuator, the microprocessor will stop the

movement of the actuator by cutting power to the motor.