Design and Theory

Linear actuators are easy to mount and operate, require no maintenance, don’t leak hydraulic fluid, are easy to incorporate into an automated process and once installed they will work reliably under the toughest conditions year after year.

What Makes up a Linear Actuator?

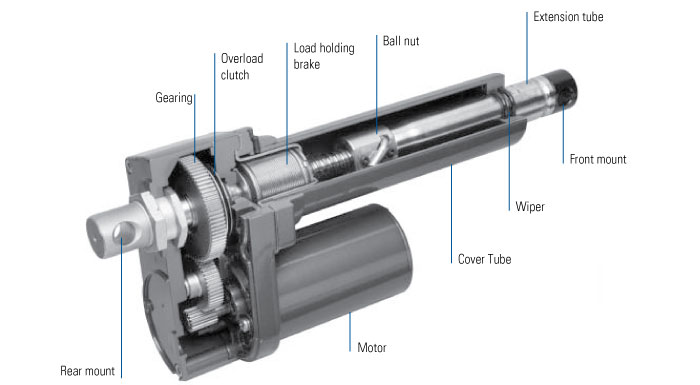

The main actuating components of a linear actuator are:

- Motor

- Gearing

- Screw assembly

- extension tube

When the motor is powered, it turns the gearing. The gearing

multiplies the torque and reduces speed of the motor. The gears turn a

screw. The nut on the screw is attached to the extension tube and is

moved in or out depending on the direction the screw is turned.

In

many actuators, there is a wrap spring brake that will hold the load

when the motor is not running. The wrap spring brake is mechanical and

will hold the load in either direction, pulling or pushing, without

power.

Lead screw vs ball screw

Some actuators are made using a lead screw and some use a ball screw. To learn more about the difference watch the video below.