Design and Theory

A screw assembly has a maximum RPM which it should operate. The nut and screw both have individual maximum RPMs that should not be exceeded. The limitations are dependent upon different factors for the screw than the nut. The maximum RPM the nut can operate and the maximum RPM the screw can operate at are usually different. Both maximums need to be considered when selecting a ball screw assembly.

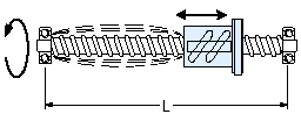

Screw Maximum RPM

Every ball screw, or any shaft, has a rotational speed at which the vibration and harmonics becomes excessive. This speed often referred to as the screw critical speed and is a function of:

- Screw length

- Screw diameter

- Type of mounting (end fixity)

For formulas to calculate screw critical speed see the sizing section. link

Ball nut maximum RPM

The ball nut maximum RPM, or the RPM of the shaft inside the nut, is limited by the velocity of the ball bearings rotating through the ball nut. Exceeding the ball nut maximum RPM may result in permanent damage to the ball re-circulation components. The ball bearings may break out of or jam the return system. If that happens complete failure of the unit will occur. Never exceed the ball nut maximum RPM.

For formulas to calculate ball nut maximum RPM see the sizing section. link