Sizing

For background discussion on this topic see the earlier section on critical speed. link

Screw critical speed (maximum RPM) calculation

A screw assembly has a maximum RPM which it should operate. For Inch screws the critical speed can be calculated using the following formula:

nc = Cs x 4.76 x 106 x dr/L2

Where

nc = Critical speed [RPM]

dr = Root diameter of the screw [in]

L = Unsupported length or length between the bearings [in]

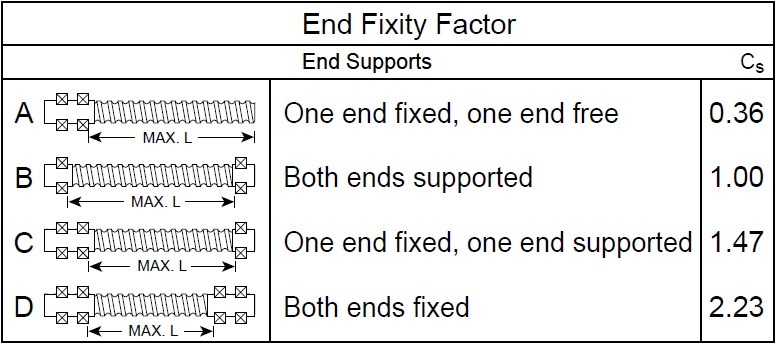

Cs = End Fixity Factor. See table below

It is recommended to operate below 80% of the screw critical speed.