Product Details

Customizing

The lead nut has a simple design that is easily

customized. Thomson is able to supply nuts with custom geometries.

Almost any shape is possible. This makes the nut able to integrate more

fully into OEM solutions and often taking up multiple functions. This is

another way that using a lead screw assembly can reduce overall system cost.

Nuts can be constructed of many different materials:

- Acetal – standard

- PPS

- PEEK

- Torlon (polyamide-imide)

- Brass

- Others

- Close backlash to maximize performance

- Loose fits to minimize alignment concerns

- Centralizing fits to allow side loading

End machining from the factory

Quick turn-around of standard end machiningAbility to manufacture to customer drawings

Advantages:

- Quality machining in one stop

- Fast lead time

Benefits:

- One supplier

- Quality work from those with experience machining and straightening ball screws

Machine to customer print

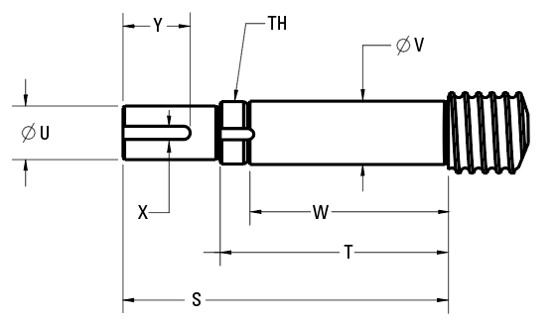

We offer a line of standard end machining options, but we will

also machine custom ends to match a customer-supplied drawing. This

image is of a drawing of the typical end machining dimensions that would

be required for us to machine the ends. Other configurations are

possible to machine as long as they are clearly drawn.