The ability to operate consistently at higher speeds is one reason that motion system designers often specify ball screws over lead screws. However, ball screws have speed limitations of their own, and understanding those will help you optimize ball screw assembly performance in applications ranging from small laboratory fluid pumps to large overhead gantries and high-performance machinery.

Ball screw basics

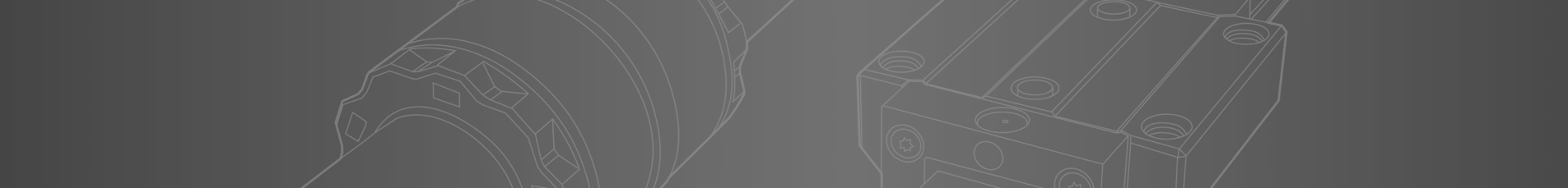

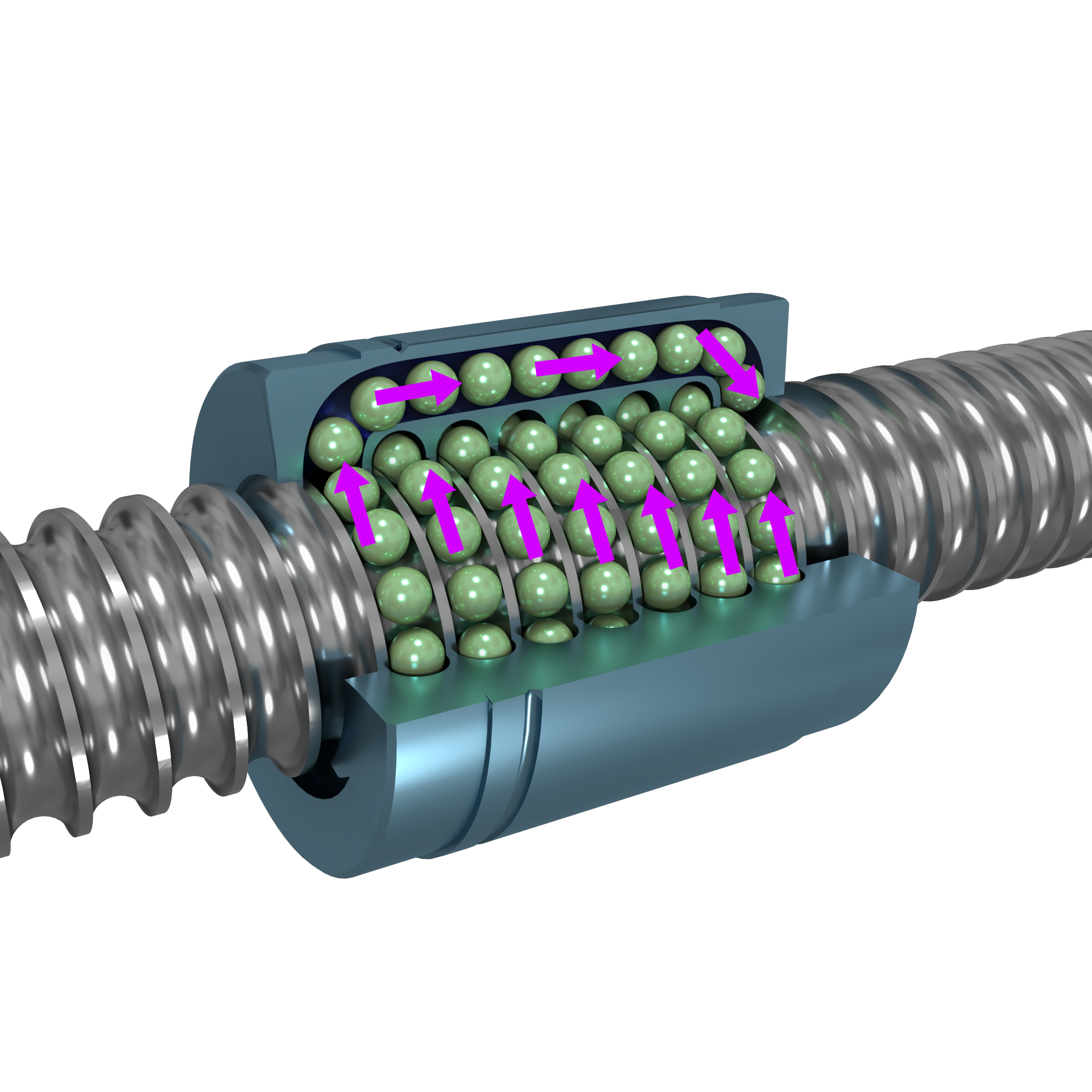

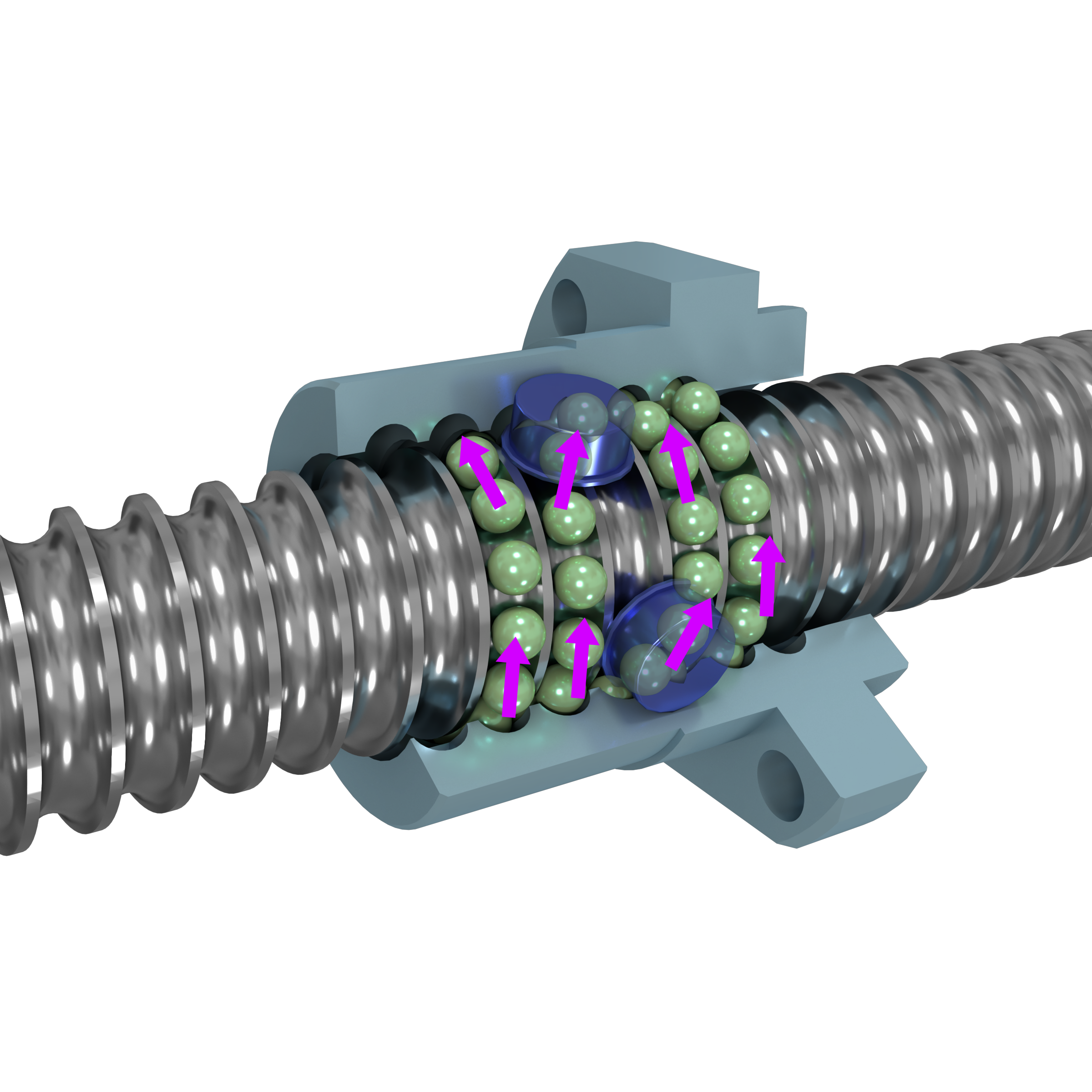

A ball screw assembly consists of a screw and a nut with recirculating ball bearings. The connection between the screw and the nut is made by ball bearings, which roll in the matching ball forms within the nut and screw shaft. This distributes forces over many bearings, giving a relatively low load per ball and a low coefficient of friction, which contributes to the capability for higher speed operation (Figure 1).

Figure 1. Ball screws have a low coefficient of friction because the load is distributed across multiple bearings, which recirculate while the shaft turns.

The screw and nut usually have unique maximum RPM limits, so selecting the most effective ball screw assembly requires attention to both.

Ball screw design features limiting maximum RPM

Primary screw shaft design features impacting maximum RPM are end mounting, screw lead and screw diameter.

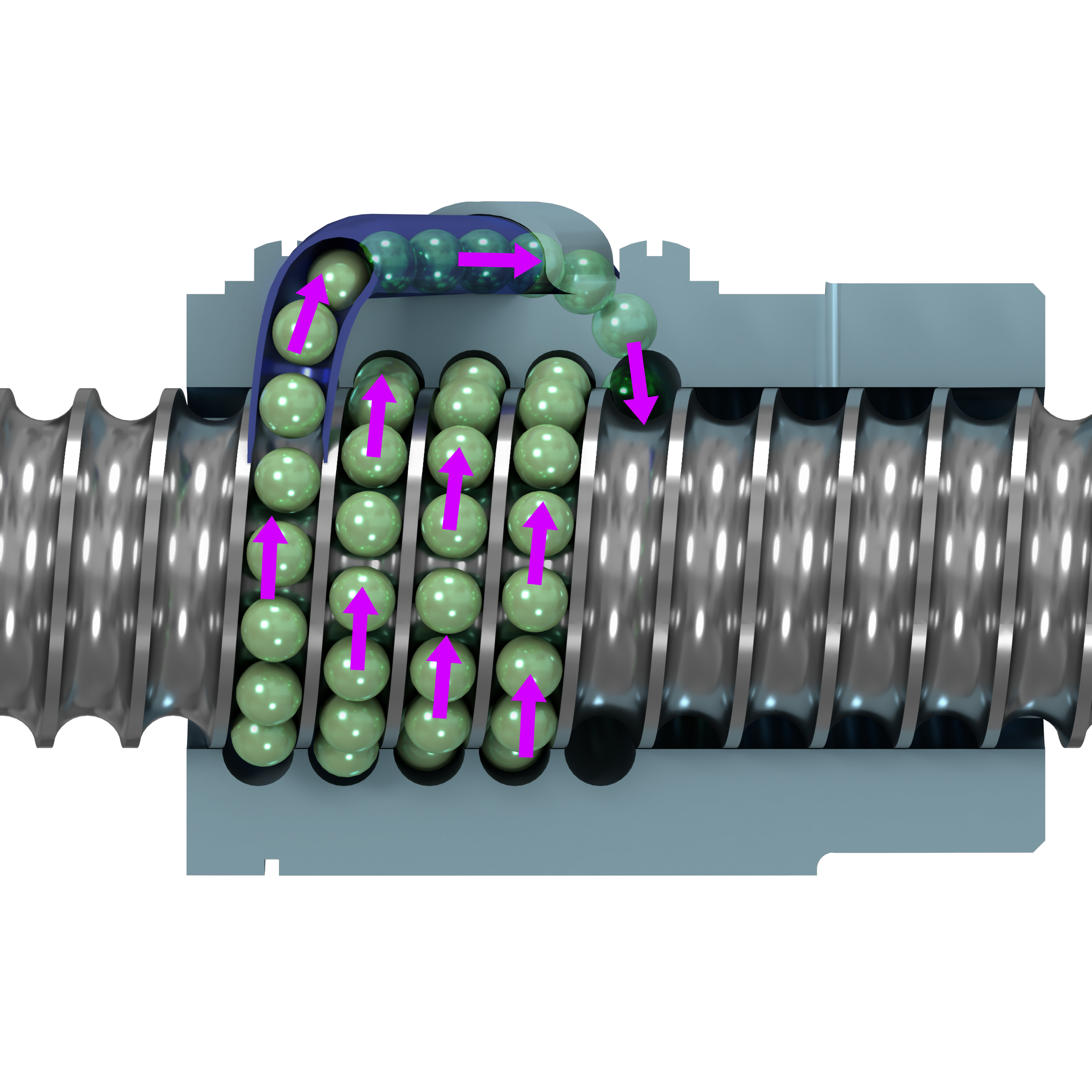

Every ball screw has a natural frequency at which it vibrates excessively, which is known as its critical speed. When the application speed aligns with the critical speed, the screw vibrates in harmony (Figure 2). Imbalances inherent in the screw then resonate with it, causing excessive bending, bowing, vibration and eventually, failure.

Figure 2. The screw shaft can vibrate at high RPM.

End mounting

Mounting options include: fixing it at one end in a thrust bearing, supporting it at both ends in floating bearings, fixing it at one end while supporting it at the other end in a floating bearing, or fixing it at both ends in thrust bearings. The highest speeds are attainable when ball screws are fixed at both ends. The fixed ends resist bending moment loads so the ball screw tries to remain perpendicular to the planes of the support bearings.

Fixing at both ends, however, can be more expensive and difficult to install than the other mounting options. When fixed at both ends, the distance between support blocks is not adjustable and can make aligning the mounting holes a challenge.

Screw lead

Higher leads will increase the linear speed by moving the nut along the screw faster, assuming constant input speed. When comparing two screws with different leads of a constant linear speed, the higher lead will decrease the input motor speed. Higher leads do, however, increase the torque required to turn the screws.

Screw diameter

Larger diameter screws increase the load capacity and the maximum RPM rating. Smaller diameter long screws will have a lower RPM. With the same lead, the larger diameter screw will have a higher speed rating.

Ball nut features limiting maximum RPM

The ball nut maximum RPM is limited by the speed of the ball bearings circulating through the ball nut. Exceeding the ball nut maximum RPM may result in permanent damage to the ball re-circulation components. The ball bearings may break out of or jam the return system, potentially resulting in complete failure of the unit.

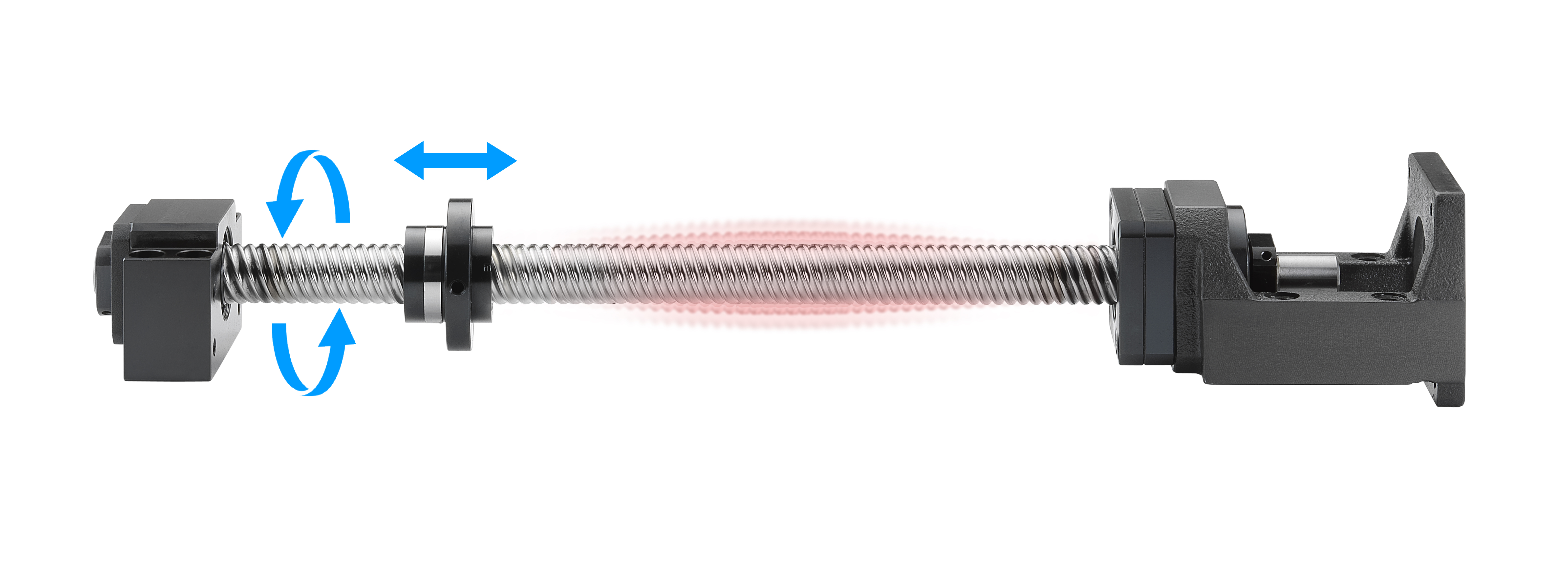

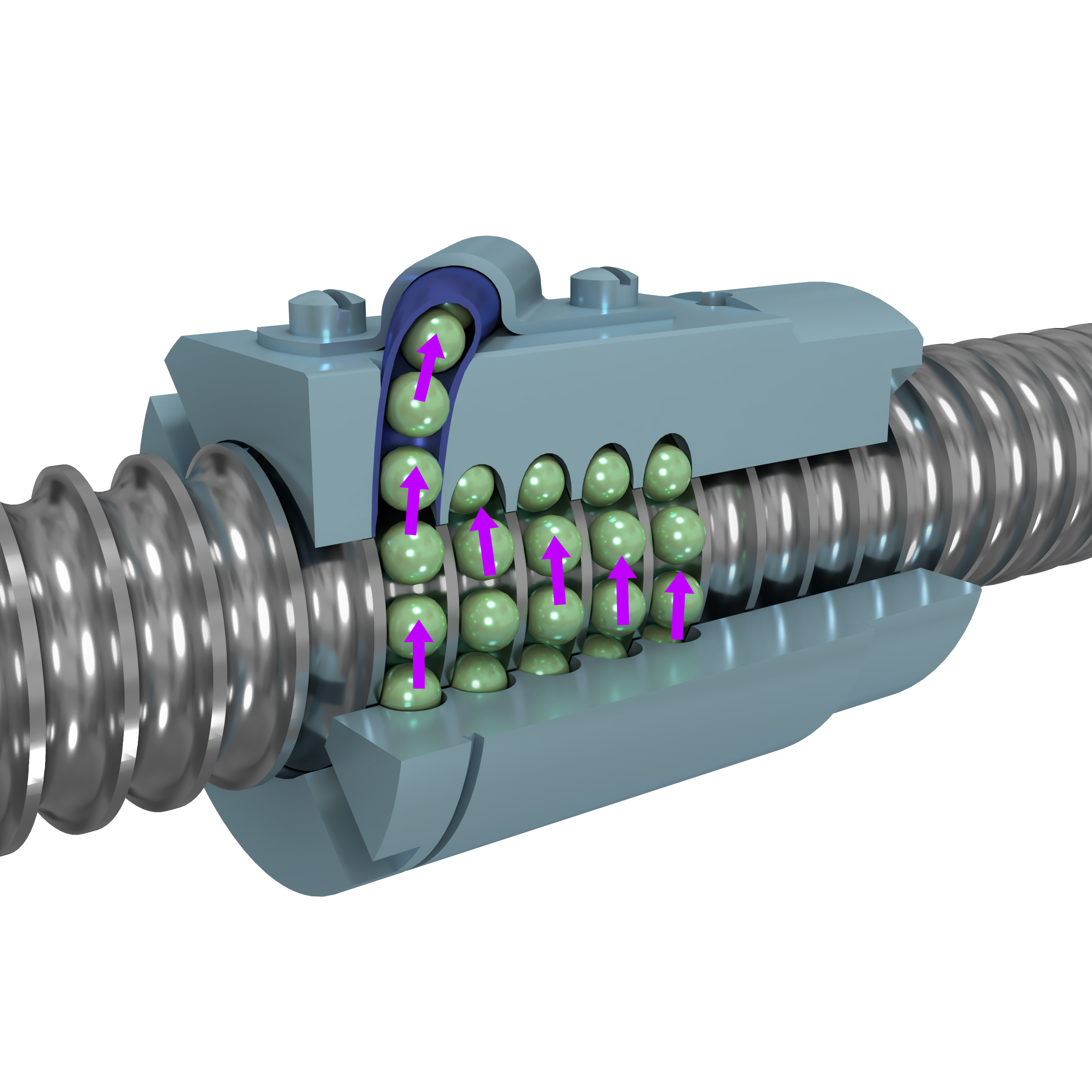

There are three major types of returns systems: internal, button and external (Figure 3). The purpose of the returns is to provide recirculation of the ball bearings in the nut. The return system design has an effect on the nut’s speed limitations. The external return systems typically utilize a small finger that extends into the ball groove to deflect the ball into the return path. At high speeds, this finger can flex from the ball bearings hitting it and eventually break off. The button and internal designs are generally more robust and typically can operate at higher speeds than the external return system.

Figure 3. A comparison of ball return systems (from left to right): internal, button and external.

Conclusion

A system optimized for speed above all else would likely require the following:

- Fixed end supports for the screw assembly

- Higher leads to increase linear speed

- Large-diameter screws to increase the load capacity and the RPM rating

- Internal return systems for the ball nuts

Many other factors come into play, however, including load characteristics, positional accuracy, repeatability, required life expectancy, dimensional constraints, input power requirements, environmental conditions and available budget.

The impact of most factors affecting speed can be calculated. Ball screw manufacturers typically recommend maximum speeds for their products and provide tools that will help you precisely measure the physical tradeoffs.

The maximum speed for a 1” diameter screw like this one will vary greatly depending on length – ranging from 2938 RPM at 36” and 184 RPM at 144” (rated at 80% of its critical speed, simple supports). Values can be referenced in the Machinery Handbook. Image courtesy of Motion Industries.