Product Details

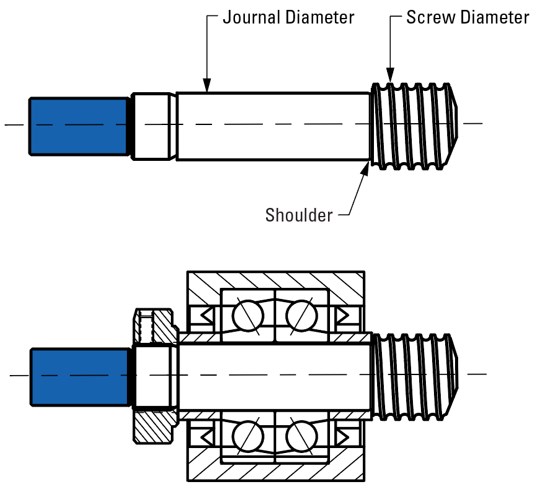

To fit a bearing support to a ball screw, a bearing journal must first be machined into the screw. The maximum diameter of the journal is limited by the screw geometry. Enough of the screw must be machined away to provide a shoulder for the bearing to seat against. The recommended maximum journal diameter is usually near the ball screws root diameter.

Thomson offers end machining at the factory

Quick turn-around of standard end machining

Ability to manufacture to customer drawings

Fast lead time

Quality work from those with experience machining and straightening ball screws

To attach a ball screw to a drive system, a drive extension is machined into the screw. When ordering a ball screw assembly with bearing blocks or a ball screw with standard end machining, it is important to specify if a drive extension is wanted on one or both ends. The shaded area in the diagram above represents the drive extension. See the specific end machining details in the product catalog or specifications on the web.

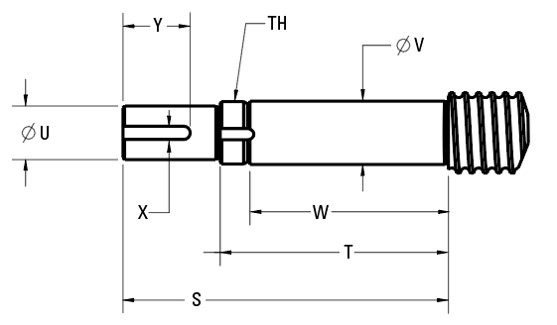

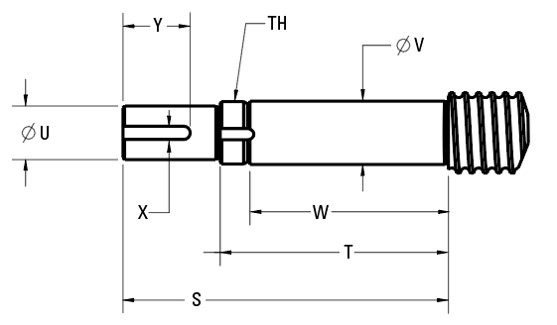

Typical dimensions for end machining

At Thomson we offer a line of standard end machining options, but we will also machine custom ends to match a customer-supplied drawing. This image is of a drawing of the typical end machining dimensions that would be required for us to machine the ends. Other configurations are possible to machine as long as they are clearly drawn.

Thomson offers end machining at the factory

Quick turn-around of standard end machiningAbility to manufacture to customer drawings

Advantages

Quality machining in one stopFast lead time

Benefits

One supplierQuality work from those with experience machining and straightening ball screws