Design and Theory

One of the improvements of the Super and Super Smart bearings over the original "A" bearing design is the ability to self-align. How does self-alignment work in a linear bearing? Read on to find out.

Bearing race design

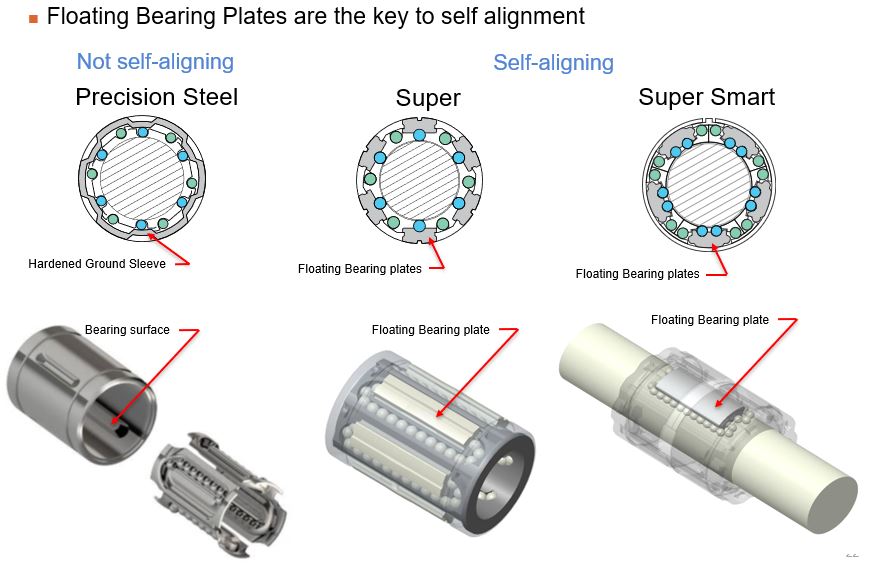

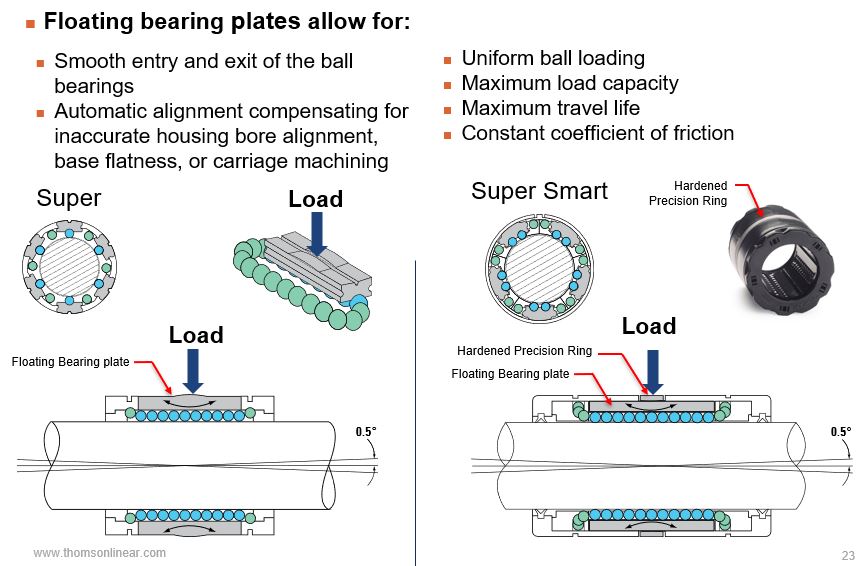

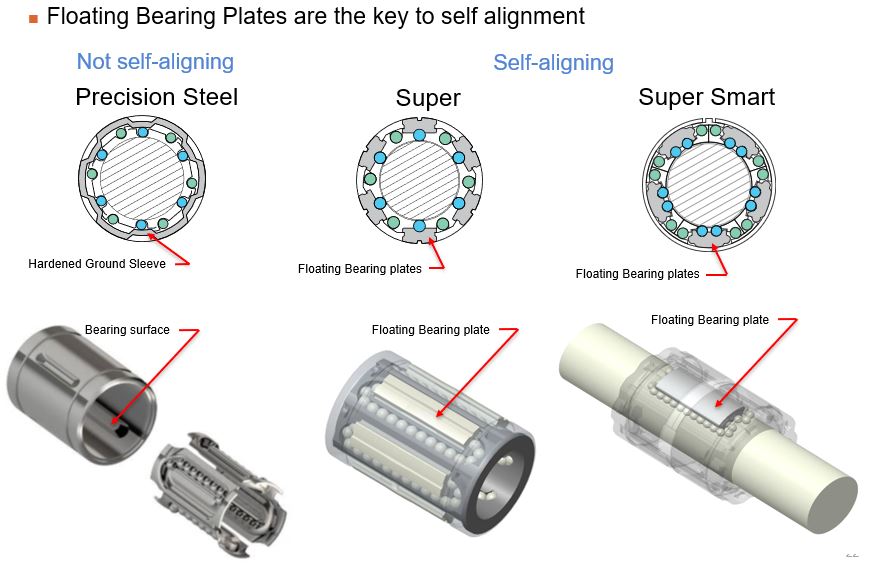

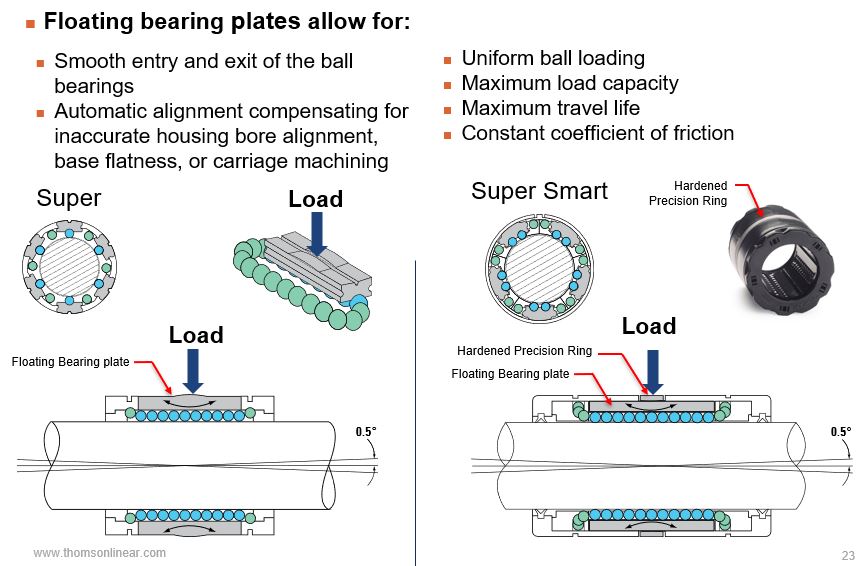

Precision steel linear bearings have a one-piece steel sleeve. This solid sleeve is unable to self-align. Super and Super Smart bearings are made with floating bearing plates. These plates are the key to self alignment and enable the bearing to self-align up to 0.5 degrees.

Floating Bearing Plates

Super and Super Smart linear bearings have floating bearing plates. While the floating bearing plates in both have similar effects, there are some important design differences.

The top of the Super Bearing’s plate has a radius or crown. The crown allows the plate to rock back and forth and provide internal self alignment. The crown on the plate would be pressed by the housing that the bearing is installed in. If the housing is soft, it is possible, over time, for the crown to wear or be pressed into the housings material. This could result in misalignment or restriction of the bearing plate.

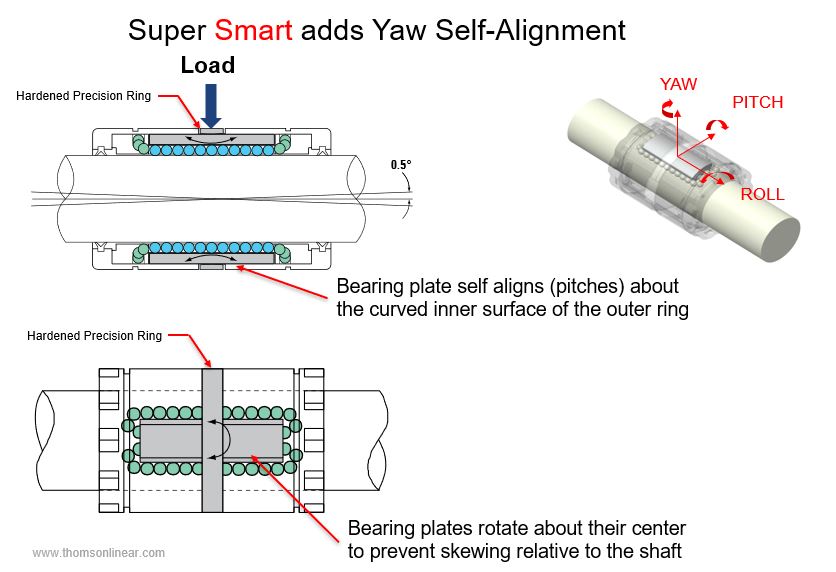

In the Super Smart, the alignment design is further improved by putting a band around the bearing plates and putting the crown on the inside of that band. The rocking motion is between the hardened bearing plate and the hardened band around the bearing. This greatly reduces the chances of the bearing digging into a housing with soft material.