Design and Theory

How is accuracy class defined?

The accuracy class of a profile rail bearing is defined by three tolerances:

- Running Parallelism

- Assembly Accuracy

- Pair Variation

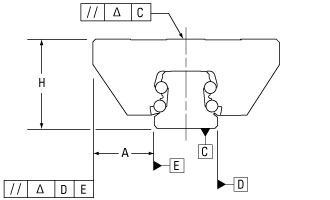

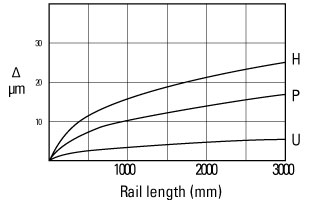

Running Parallelism

Running Parallelism

describes the tolerance on H and A as a function of axial travel,

measured from one carriage down the length of the rail. This is

analogous to straightness of travel. As such, parallelism describes

attributes of the rail only.

Assembly Accuracy

Assembly accuracy describes the tolerance on H and A as a function of a carriage – rail assembly, measured from the nominal dimensions.

Pair Variation

Pair variation describes tolerance on H and A as a function of carriages at the same position on a common rail. Pair variation describes carriage precision only.

System Accuracy

The accuracy class selected will partially determine the accuracy of the system. Other factors such as mounting surface flatness and straightness also significantly affect system accuracy.