Given the ease with which we can manoeuvre vehicles through winding roads and around tight corners, it may seem that there is little room for improvement of modern power steering systems. The engineers immersed in over-actuated vehicle technology at Sweden’s KTH Royal Institute of Technology and Integrated Transport Research Lab (ITRL), however, think otherwise. They are working to determine whether replacing conventional hydraulic steering technology with compact electromechanical technology could bring performance, cost, maintenance, sustainability and flexibility advantages.

What’s wrong with today’s steering?

The power steering system in most cars today is built around a large steering column that occupies a significant portion of the driver’s side of the car. By turning the wheel, drivers direct pressurised hydraulic fluids to actuators on the front wheel assembly, which enables the wheels to pivot left or right on the ball joints by which they attach to the suspension system. This setup works well up to a point but has many limitations.

For one, the steering post takes up a significant amount of space and adds weight to a mechanical system that is complicated and costly to maintain. If the steering system is damaged in a collision, for example, cost of repair or replacement is a major expense. Hydraulic steering systems also require regular maintenance. Power steering fluid must be replenished regularly, and potential for leakage jeopardizes safety by compromising steering performance.

Energy efficiency is an issue under review. “The traditional steering system is powered by direct connection to the engine, so at idle, you are giving up power to the systems, but when you drive at high revs, you over-power,” said Director of ITRL Peter Georén, an expert on transport innovation. “The design trend is to use the engine more for propulsion than for powering the subsystem.”

Another limitation of the conventional steering rack is that only the front wheels turn and do so with limited degrees of movement. This, for example, makes squeezing into a tight parking space challenging and requires the widely dreaded operation known as parallel parking. Despite the fact that some newer vehicles can do this for us, it would still be much more efficient if a car could enter a parking spot perpendicularly. Apart from parking, having multiple steering actuators enables control of the car to make the ride more pleasant, safer with reduced rolling and curve resistant.

Although not currently a part of the steering system, adjustment of the camber, the vertical alignment of the wheel in relation to the car, is a precision operation that must be done with special equipment whenever a pothole or other trauma throws it off. If this adjustment could be done more easily – even automatically – it could save time and money, make for a smoother drive with less tyre wear, and when needed, increase the lateral grip to improve safety.

The steer-by- wire initiatives are part of a broader set of environmental and sustainable transport challenges that KTH and ITRL are working on. ITRL conducts its testing on a 400 kg research concept vehicle (RCV), which can carry two passengers and reach a speed of 70 km/h. Figure 1.

Figure 1 - Steering Assembly, photo Matthias Tidlund.

On each wheel of the RCV is a steering apparatus, which is controlled by a linear actuator. Traditionally, pressurised fluid delivered via hydraulic tubing provides the steering force, whereas in the ITRL’s RCV, electric wires replace hydraulic tubing and activate the small motor built into to the actuator housing. Drivers control the electrical signals using a steering wheel, but this works more like the controller of a video game than the conventional post and tubing system.

To equip the system for testing over-actuated technology, the ITRL team determined that the RCV would need eight actuators: one on each wheel for controlling the steering and another on each wheel for controlling the camber. Finding the right linear actuator took some time. They submitted the specifications to a number of vendors, most of whom could meet the specs at a higher voltage or on AC. Only Thomson Industries could meet all of the specifications exactly as required. Thomson supplied four high-speed Max Jac MX24-B8M10E0 actuators to perform the steering functions and four Pro Series actuators to change the wheel camber inclination.

As expected, the new electric linear actuators were more responsive than the hydraulic actuators because of the speed with which electricity travels across a wire. Moreover, the digital control combined with the specially engineered steering architecture provided a level of flexibility not possible with conventional actuation. It is this capability, for example, that could replace parallel parking with perpendicular parking or someday enable automatic realignment during driving to reduce rolling resistance or adjust after hitting a pothole.

Trial by fire

The testing regimen involved running the car with full load and making sustained turns. Static turning puts more stress on the system than turning while the car is in motion, and it wasn’t long before operating near the limits of the linkage configuration began to take its toll. The windings on the actuator motors overheated and began to burn.

Using different actuators was not an option as it had already been established that only the Thomson actuators could meet the required performance specifications. Attention turned to the stock motor that came with the actuator because it was not designed for conditions as extreme as those used in the ITRL test. Georén and his team tested the idea that a motor wound differently might deliver the required performance without burning.

Motor comparisons

The test was carried out in a unique collaboration involving a KTH intern Bruno Verde and Thomson engineers. They evaluated several motor alternatives against geometrical and electrical constraints and considerations that would allow continuous duty cycles at higher forces. Selection factors included the required input torque needed for certain force output, motor-heating characteristics and the ability to match current mounting.

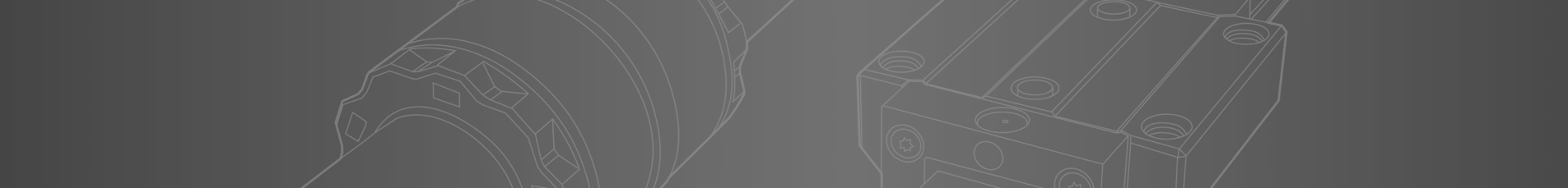

Figure 2 shows the results obtained from the motor chosen for its compatible size, higher torque and thermal capabilities resulting from lower winding resistance and quality build.

Figure 2: New motor testing results.

Under a load of 1080N, the alternative motor required only 2.8A of current to achieve the required torque, keeping it well within its thermal limits to operate continuously. After almost 1000 seconds, the motor casing had reached only 45 °C with no signs of burning. After 23 minutes, temperatures rose to 50 °C, and there was still no burning. Verde calculated that the motor would reach a steady temperature of 80 °C at the winding when consuming 2.7A constantly, which was well within the motor’s specifications. This confirmed the feasibility of using the alternative motor for the steer-by- wire application.

Taking to the road

The alternative motor was not a drop-in replacement for the stock motor as it required drilling three new holes. New teeth pinions had to be ordered and machined to be adapted to the diameter shafts of the new motors.

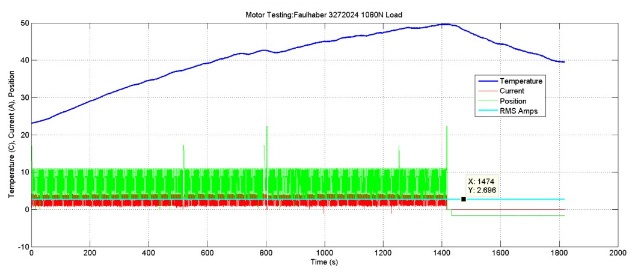

The modified actuator was mounted in one corner of the car to test static steering performance using the testing cycle and controller. Teams tested the vehicle with no passengers, then one and two passengers. As seen in the figure below, with two passengers, the actuators used 1.5A RMS, which roughly corresponds to an output force of 600N in the actuator and can be maintained at a 100% duty cycle with this motor.

Figure 3: Results with 2 passengers on board.

The motor was then connected to the RCV steering controller to test its performance with the whole system. The stronger motor enabled increasing the steering angle by approximately five degrees.

Going forward

The actuator modification delivered a high-powered system that met the improved performance targets and produced twice the force of its predecessor and greater responsiveness without overheating. The researchers believed that even higher forces (200 N at 5 amps, for example) were possible for short bursts, however, more extensive testing and analysis of the system would be needed to determine the mechanical safe limits.

Georén estimated, “It could be five years before steer-by- wire technology actually hits the street, with the first instances likely to be in industrial applications in which high manoeuvrability is important, such as forklifts and cargo carriers.” “Nonetheless, Thomson actuators have contributed to the creation of an important milestone.

“Many companies talk about working with students and academic institutes, but actually doing it is something else. Thomson should be very proud; they used the power of many people to develop a really great product.”

For Further information on Thomson Industries Inc.’s Max Jac® Heavy Duty Electric Linear Actuators and Electrak Pro Linear Actuators mentioned in this case study, please visit the following links:

Max Jac Actuators: http://www.thomsonlinear.com/website/com/eng/products/actuators/maxjac.php

Electrak Pro Linear Actuators: http://www.thomsonlinear.com/website/com/eng/products/actuators/electrak_pro.php

Thomson was able to provide unique collaboration and customisation that aligned to the needs of

the project. Pictured, KTH President Peter Gudmundson and Matthias Tidlund tests the RCV for

the first time. Photo courtesy of Matthias Tidlund.

Thomson’s Max Jac ® linear actuator design provides both high durability and performance,

delivering high speed, efficiency and accuracy from a compact envelope. Photo courtesy of

Matthias Tidlund.

The Max Jac ® linear actuator is built to perform in harsh environments and materials, such as

fertilisers, mud, sand, high-pressure water, slush, saltwater, snow, heat or heavy vibrations.

Photo courtesy of ITRL.

The Thomson actuator modification was able to deliver a high-powered system that produced

twice the force of its predecessor and greater responsiveness without overheating.