By Howard Horn

Product Manager

Thomson Industries, Inc.

www.thomsonlinear.com

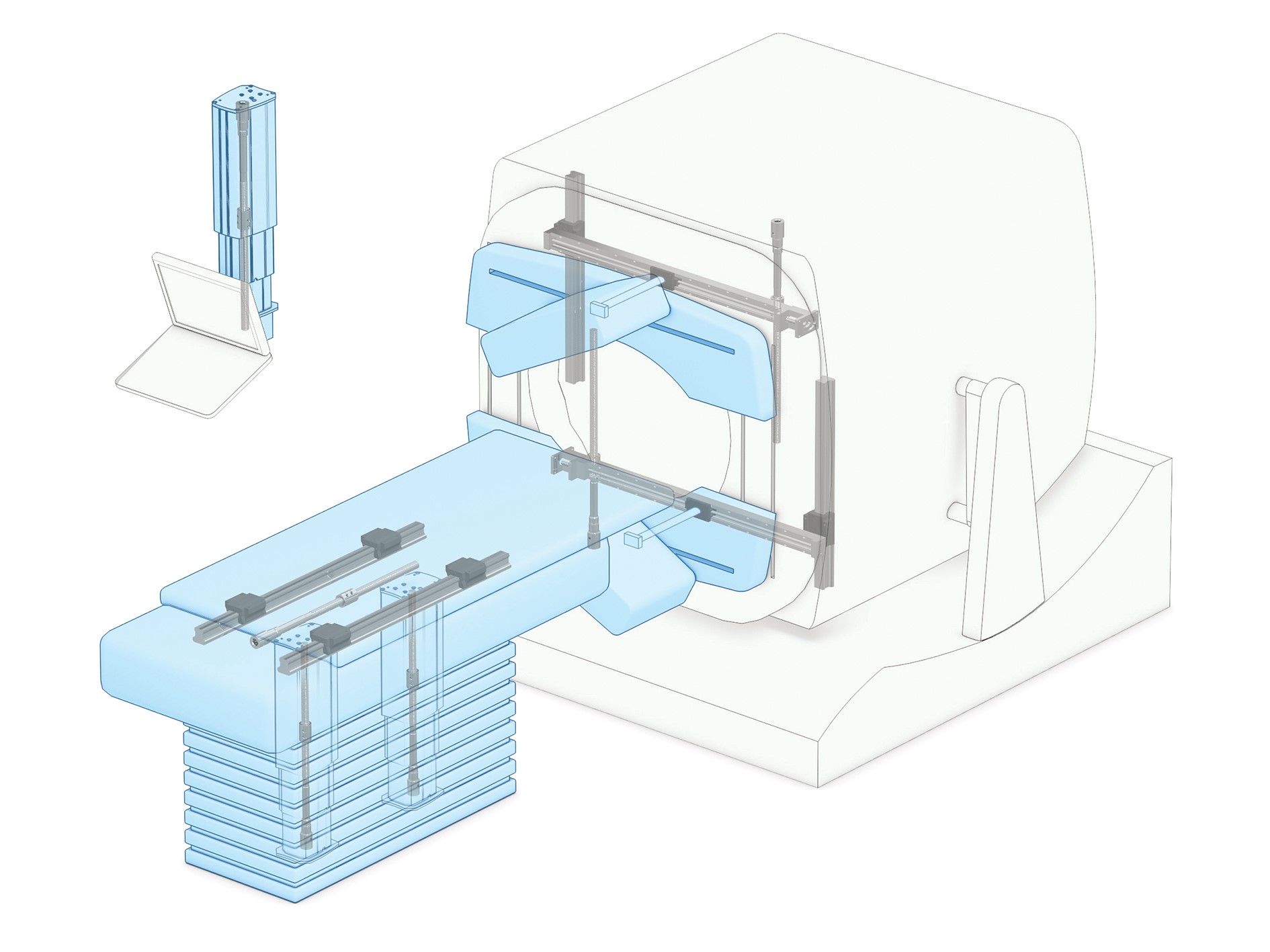

CT scanners have far greater accuracy than X-ray technology but place more demands on patients. Getting the high precision, 3-dimensional images necessary for accurate diagnosis requires patients to lie still on a table moving through a magnetic field created by a large ring of magnets that rotates around them. Although the fundamentals of these designs are limited by the laws of physics and economics, over the years, medical equipment manufacturers have made great strides in refining system mechanics to maximize patient comfort. They have, for example, reduced the duration of a single rotation from hours to below 500 milliseconds, which has shortened sessions dramatically.

Given the ongoing need for improving patient comfort and the speeds at which heavy – up to one ton – components must move smoothly, the selection of motion control components is paramount. Accomplishing this requires careful selection and integration of many different motion technologies, among the most impactful of which is the gearing that supports table motion, reliability, noise level, load bearing and footprint.

The power of distributed gearing

Planetary gearheads are among the most widely used gear configurations for medical applications. In this sophisticated arrangement, three to five spur gears, known as planetary gears, rotate about a central pinion or “sun” gear. Distributing the load in this way helps CT designers meet many key design objectives:

- Smooth table motion. Ensuring that the patient table moves accurately and smoothly is critical to patient comfort. Sharing the load among multiple gears enables a more controlled step-up in torque, contributing to smoother motion. This is especially important as tubular detection unit advancements in the latest generation of devices have made it possible for the patient table to be moved at speeds up to 100 mm/s.

- High reliability. Having to repeat a procedure to get a desired result takes its toll on patients who may already be stressed out about having to spend extended time in a narrow chamber. Planetary gears have characteristically low backlash, which reduces positioning errors.

- Low noise level. Even though CT scanners are not as noisy as MRI systems, quiet operation is still important. Every decibel reduced helps decrease involuntary patient movement, which can also make scans unusable. Quiet motion system components also make for easier communication of instructions from medical personnel to patients, which also expedites the time to achieve a usable result. In addition to reducing positioning errors, the low backlash of planetary configuration reduces vibration and noise.

- Load bearing flexibility. Systems must be capable of handling many different load sizes. The currently applicable safety regulations require a maximum table load of 280 kg. This value is expected to increase to 340 kg in the near future. Therefore, the motion system must also be able to adjust to this weight reliably. Distributing the load attached to the output shaft amongst all gears enables the handling of much larger loads. It also reduces maintenance requirements and extends the life of each gear.

- Footprint. All components in medical devices must be entirely enclosed, and there is a limited space in the gantry, which means there are also limits on the physical size of the motors. Distributing the load provides the highest possible torque within a confined space, which enables use of a smaller servomotor, keeping the overall size of medical equipment to a minimum.

“When compared to other technologies such as parallel shaft, spur gearing, planetary gearheads usually offer much higher torque density due to the load sharing between the planet gears. This allows our customers to not only reduce the overall footprint but increase the safety factors in their design improving the overall safety of the patient,” said Michael Dolpp, Vice President and General Manager of Thomson Deltran/Micron/Harowe Products.

Thomson Micron gearheads and other components provide smooth travel and consistent quality control to heavy duty applications like medical imaging systems

Growing medical applications for planetary gearheads

Understandably, medical equipment is a fast-growing and competitive market with OEMs looking at price and technical advantages over their competitors. Additionally, the changing regulations and new opportunities are triggering innovation and performance in motion control.

“Another benefit that has driven more applications to planetary gearing, not only in the imaging space but across the entire medical arena, is the reduction in noise. More and more customers have been asking for lower decibel levels along with smoother operation for the comfort of their patients,” Dolpp added.

Planetary gears are also finding increasing application in other medical and patient handling equipment, including operating tables, dentist chairs as well as other complex diagnostic systems. Thomson Industries, Inc., for example, offers a complete range of planetary gears designed specifically for high-precision, motion control applications that require a high torque-to-volume ratio, high torsional stiffness and low backlash.

The Thomson Micron AquaTRUE™ gearhead

To help designers select the right gearhead assembly, Thomson also offers a free online sizing and selection tool, which has recently been updated to include even more motor mounting options, an easier-to-use customer interface and the AquaTRUE™ stainless steel gearhead product line. The Thomson Micron Motioneering® tool, available at www.micronmotioneering.com), is a user-friendly and detailed gearhead sizing tool, from which designers can choose a wide range of configuration options. This saves design time and optimizes the balance between performance and installed cost. Outputs include 3D model downloads, list prices, delivery times and detailed ordering information.