Automated guided vehicles (AGVs) in factory settings are typically used less frequently than in large distribution centers, resulting in the motion profiles being more complex and specific to a factory’s operations. To meet these needs, industrial OEMS have traditionally engineered AGVs almost from the ground up. However, designing a one-off AGV for an end-user can be expensive and require long lead times.

As the demand for specialized industrial AGVs grows, OEMs are increasingly meeting customer needs for special functionality and economy by offering standard AGV models that can be easily adapted to a wider range of factory floor applications. Equipping AGVs with such versatility is an evolving new generation of smart electric linear actuators armed with onboard intelligence and communications, extended durability, modular assemblies and flexible mounting options.

AGVs on the plant floor

Industrial AGVs, which include carts, tuggers, self-driving forklifts and mobile robots, improve manufacturing efficiency. These machines relieve much of the human lifting involved in material transport, such as delivering materials and components to a production line. An assembly line operator sitting at a workstation might message their need for a component to a logistics computer system. The management system forwards the request to the AGV management software, which dispatches the nearest vehicle to the task based on priority and optimal pickup and delivery motion. After the AGV completes the job, it signals the control system to proceed to the next step in the process.

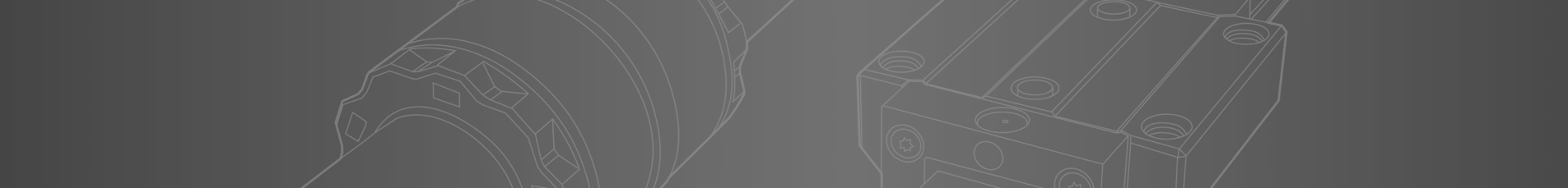

While AGVs may differ in form, they share a common functionality of aiding manual labor and increasing material handling efficiency. Electric linear actuators with integrated communications (shown installed in each example) are key in designing AGVs as part of a smart factory. The Thomson Electrak® HD actuator (shown installed in the top AGV) is available with a rear mounting flange, making it more compact and easier than ever to design linear motion into automated equipment. (Image courtesy of Thomson Industries, Inc.)

Much of an AGV’s work involves sliding under pallets and using actuators to raise them so that contents can be transported wherever needed. In order to meet the ambitions of modern plant floor process innovation, new AGV applications demand more complex motion profiles and often require accessories such as grasping arms, claws and clamps.

Onboard intelligence and communications

Key to this new generation of actuators are a microprocessor and communications via an open protocol such as CANopen® or SAE J1939 CAN bus. AGVs equipped with such smart actuators and communications provide maximum flexibility in designing movement profiles. Where getting this kind of control might traditionally have required implementing external devices such as encoders, today’s smart devices do it all with a combination of software and integrated feedback devices for an all-in-one solution.

The host computer knows the state, position, speed, direction, and power supplied to the AGV, and with such information at hand, designers can program the AGV to adapt to changing scenarios. For example, by knowing how much weight the vehicle is carrying and comparing it to what a plan might call for, production supervisors can evaluate the performance of the AGV. By reading pressure from strain gauge sensors on a gripper arm, they can set it to reduce force to prevent the gripper from crushing an object. Conversely, operators could increase the force to prevent it from dropping the object in the event of a bump or other disruption. Through real-time communication among four actuators supporting a stack of pallets, the AGV can be programmed to move only two actuators to tilt the pallet to compensate for load shifts or imbalance.

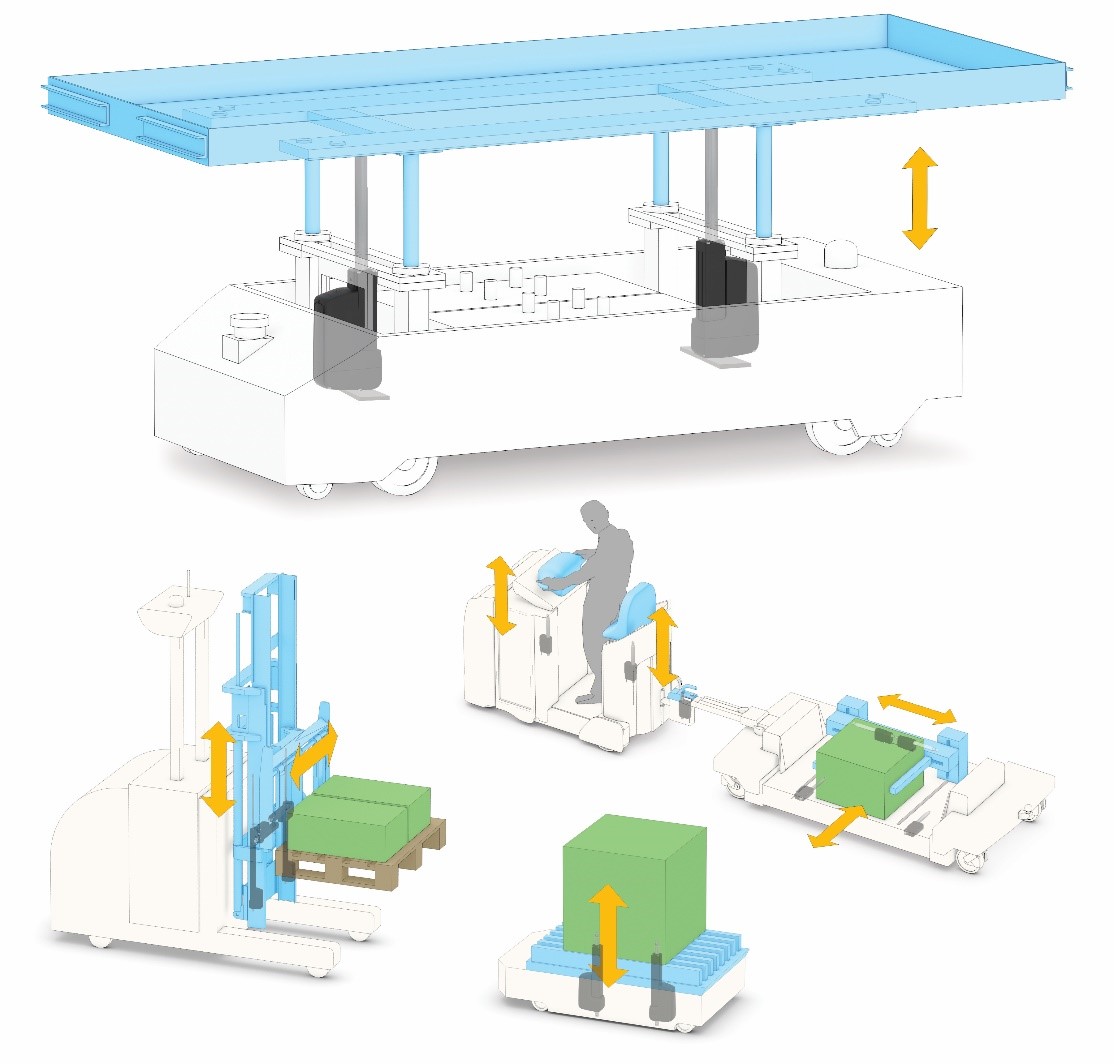

The automation needs of factory warehouses are becoming increasingly complex in order to meet industry standards and demands. Today’s AGVs feature advanced intelligence to help reduce maintenance and improve uptime. (Image courtesy of Thomson Industries, Inc.)

Having such detail on the AGVs’ movement can also reduce maintenance costs and improve uptime. By tracking the AGV actuator and the travel distance and comparing it to the predicted lifecycle, for example, maintenance teams can reduce downtime by replacing components proactively before they break.

Mixing and matching other motion components

An actuator assembly includes a gearbox with several different gear reductions that can be adapted for load and speed, a lead screw, a nut that could have multiple capabilities, and a motor that might be either brushed or feature brushless steppers. Modern electric actuators offer more flexibility in configuring these options within the same envelope. And when partnering with a manufacturer whose engineers can collaborate with yours and customize the actuator to meet your specific application requirements, you’ll benefit from a quicker, less expensive and more accurate solution.

If the application calls for higher speed, the designer could use a lower gear reduction. If it requires optimization for lifting force, they might use a higher gear reduction to get maximum current that can adjust the voltage. If safety is a primary concern, they might integrate limit switches for an interlock design. One of the most significant choices impacting AGVs, however, is to optimize around the duty cycle by using brushless motors instead of the brushed variety.

Expanding application horizons with brushless motors

Where the brushed motor may provide duty cycles of 25 percent, brushless motors can deliver up to 100 percent duty cycles because they run without wearing down contact brushes with high current and heat. Inexpensive brushed motors are effective and useful for simpler distribution warehouse applications because even though volumes are high, movements are short, simple, up-and-down strokes that do not generate much wear on the brush material. For more complex operations involving frequent starting and stopping, load shifts, higher speeds and external accessories, however, a brushed motor would burn out faster than a brushless design. Whether the application requires cycling every 10 minutes or millions of cycles 24/7, brushless motor-driven actuators such as the Thomson Electrak® LL can expand the range of applications for AGVs.

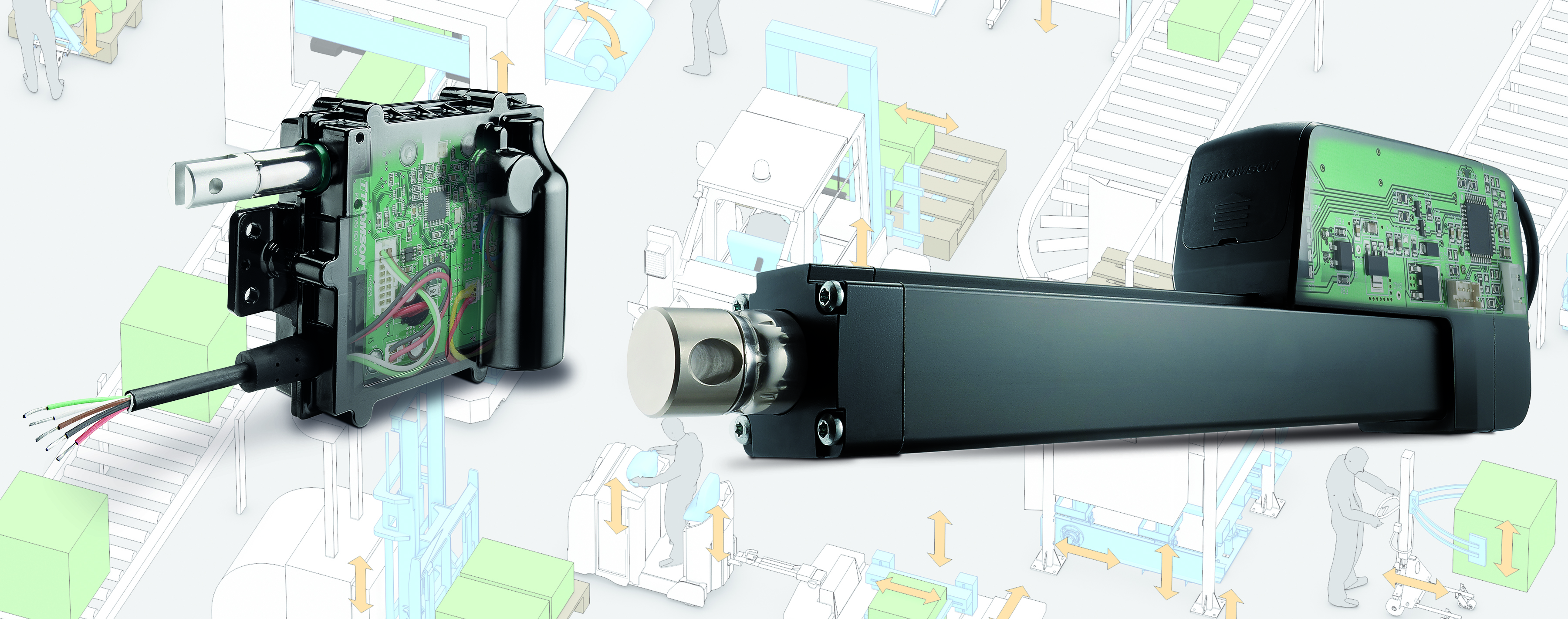

Smart electric linear actuators, such as select models of the Electrak series from Thomson Industries, have been designed with the intelligence requirements of automated factories in mind. (Image courtesy of Thomson Industries, Inc.)

Flexible mounting

Modern actuators provide more flexibility when it comes to mounting as well. Traditional vertical mounting is always an option, but certain applications might benefit more from a horizontal orientation that extends or retracts to control a scissor jack that is fixed on one side and free on the other. A vertical or horizontal mount may affect safety considerations and involve adding a foot mount on the rear of the actuator. Another available option is to use a threaded end instead of a plain rod, decreasing overall installation length for tight design envelopes. The latter two options can be found on a retrofit version of the Thomson Electrak HD electric actuator that was developed specifically for AGVs, mobile equipment and industrial automation.

New routes for AGVs

Smart electric actuators, in combination with modular assemblies, brushless motors and mounting options, can provide a new range of flexibility for AGVs that would not have been considered feasible only a decade ago. Incumbent designs could never cost-effectively deliver the necessary control, intelligence and modularity. As a result, AGVs can now go more places, do more things and bring more customer value.