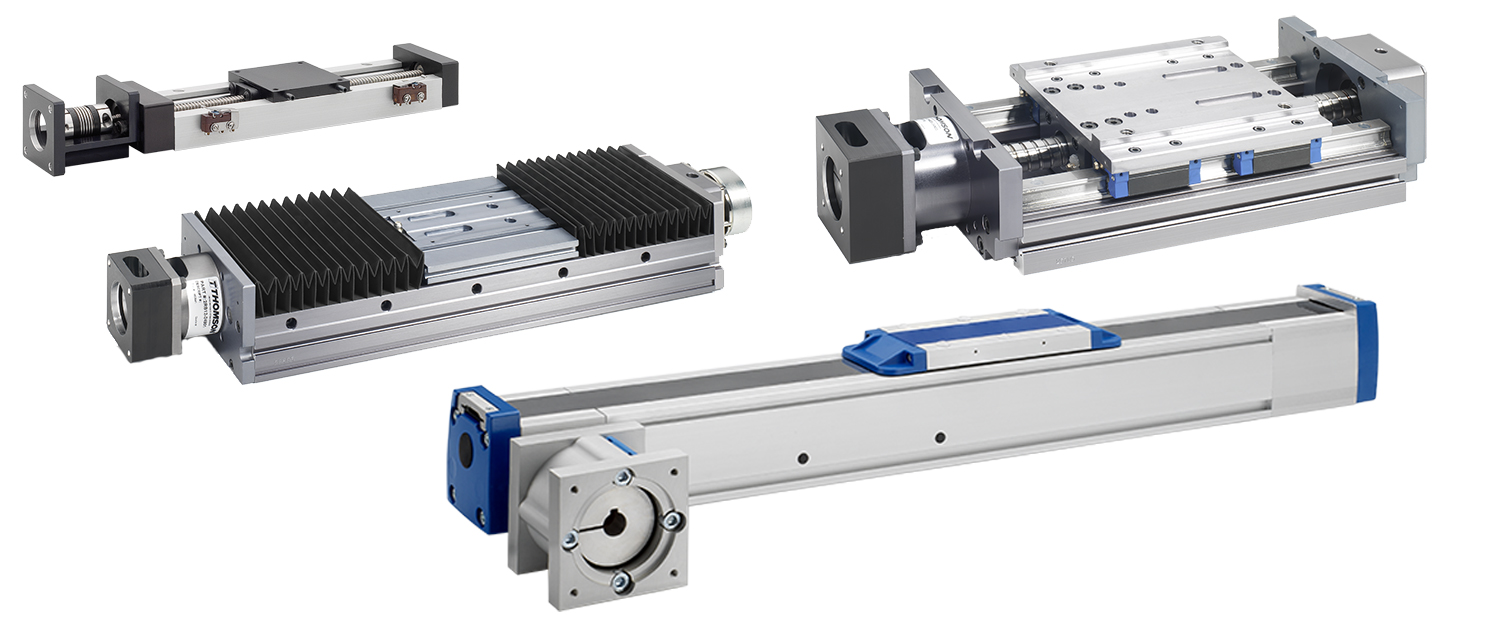

Linear Slides

The diverse range of Thomson linear slides can be configured to work in harsh environments, at high speeds and in high-precision applications — all while striking a balance of performance, life and cost.

What is a linear motion slide?

Screw-driven, ball-guided positioning linear slides are designed for robust applications that demand high thrust along with high-precision accuracy and stiffness. This configuration of drive and guide is just one of several pre-assembled, ready-to-install linear slides available to linear motion engineers. All provide low friction and smooth, accurate motion for a wide range of moment or normal loading configurations. A thoughtful review of the many configuration options will reveal the optimal linear slide system for a specific application.

Market applications for linear slide tables include factory automation, medical, packaging, machine tool, semiconductor, printing, automotive assembly, aerospace and food processing. From Thomson, a great range of linear slide tables are available — from simple, undriven linear guides to custom-designed, multi-axis, turnkey linear systems complete with motors, drives, controls and electromechanical accessories.

Which Thomson linear slide is best for your system?

We know that your specifications and requirements can vary widely from one application to the next, so we offer a wide array of linear slides to help match your needs. Choose from one of the product families listed below or use our online sizing and selection tool, which taps into the extensive application engineering knowledge base of Thomson experts. This intuitive tool offers you a new way to optimize your machine design in a fraction of the time it can take with manual calculations. Simply complete a self-guided, interactive series of questions and, within minutes, the tool will help you discover the perfect linear slide solution for your design.

The tool also makes it to select linear slide accessories and motor mounts for your design. Enjoy immediate access to interactive 3D models, up-front pricing, leads times and ordering via the Thomson Online Store.

Thomson linear slide families include:

2DB (SuperSlide)

The Thomson 2DB (SuperSlide) positioning table is a continuously supported system designed for rigid applications moving medium to heavy duty loads. The table comes from the factory pre-aligned and preassembled for immediate installation with mounting screws through the base. An integrated ball or lead screw assembly with standard NEMA motor mounting is supported in a dual LinearRace® rail package.

2HB (AccuSlide)

Thomson 2HB (AccuSlide) is a high-performance linear slide table based on our continuously supported, profile rail system using square rail technology. The units are designed to absorb extremely high load torques and offer superior performance life in difficult applications.

2RB (SuperSlide)

Thomson 2RB (SuperSlide) positioning slides are continuously and intermittently supported systems with integral screw assemblies in both metric and English standard units. Based on Thomson RoundRail technology, these units work well in applications where moderate stiffness and rigidity are required.

MF/TF (Movopart®/Rapidtrak®)

Thomson Movopart MF (TF Rapidtrak) rodless actuator slides provide guided linear motion through a ball screw drive and a saddle that rides along the top of the actuator to carry the load. Available in two versions, M (single nut) and MD (double nut), these ball-guided units are designed to provide high load capacity with low friction for precise positioning. They are also able to produce high thrust, high precision, stiffness and long stroke capabilities.

MG/TG (Movopart/Rapidtrak)

Thomson Movopart MG (Rapidtrak TG) rodless actuator slides provide guided linear motion through a ball screw drive and a saddle that rides along the top of the actuator to carry the load. These units are designed with low cost in mind, high speed, thrust, and stroke length capabilities. Available in two versions, M (single nut) and MD (double nut), these versions are designed to provide lighter load and speed application performance while still providing precise positioning.

MS (MicroStage)

Thomson MicroStage MS ultra compact linear slide tables are among the most compact, low-cost and lightweight ball-guided systems on the market today. The guide's design is based off Thomson Super Ball Bushing® technology and is ideal for automation in cramped areas.