Properly specified, self-lubricating bearings reduce maintenance costs, extend bearing life and are more environmentally friendly.

Motion system designers are increasingly outfitting round and profile rails with self-lubricating bearings that can significantly reduce cost of ownership, improve performance and deliver virtually maintenance-free operation. However, whether they will deliver their fullest potential depends on how the bearings have been specified, installed and evaluated for compatibility with their intended environment.

Benefits of self-lubricating bearings

For more than 10 years, self-lubricating — or lube-for-life — designs have used oil-saturated polymers in Linear bearing applications ranging from food processing to automotive assembly. OEMs are turning to these designs to make their machines more attractive and take advantage of their maintenance-free operation with longer life, increased reliability and overall lower cost of ownership.

MRO teams will accrue benefits, as their job is to keep installed bearings operational and replace them at the end of their lifecycles. They will enjoy significantly longer maintenance and replacement intervals, greater machine uptime, higher throughput and cleaner operation. They will also save money by eliminating the need for expensive lubrication systems and lubricants.

How self-lubricating bearings work

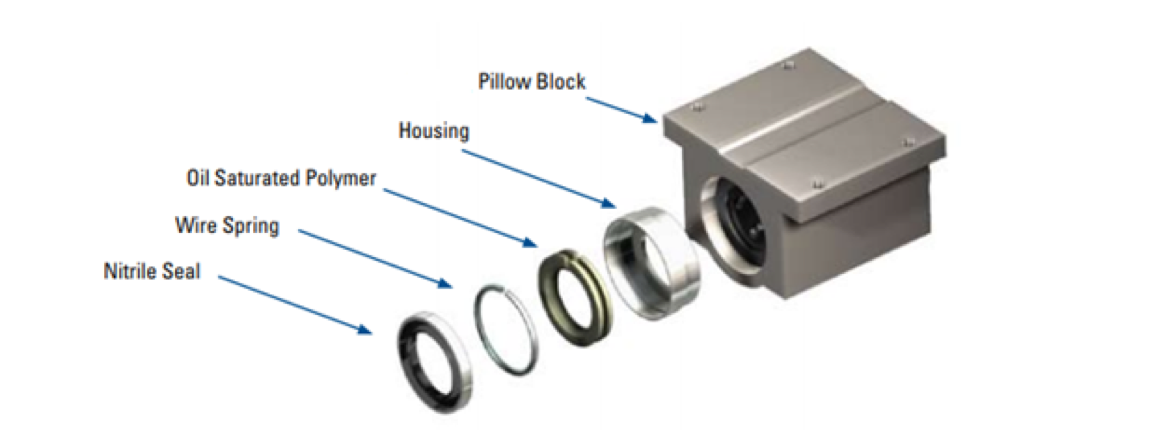

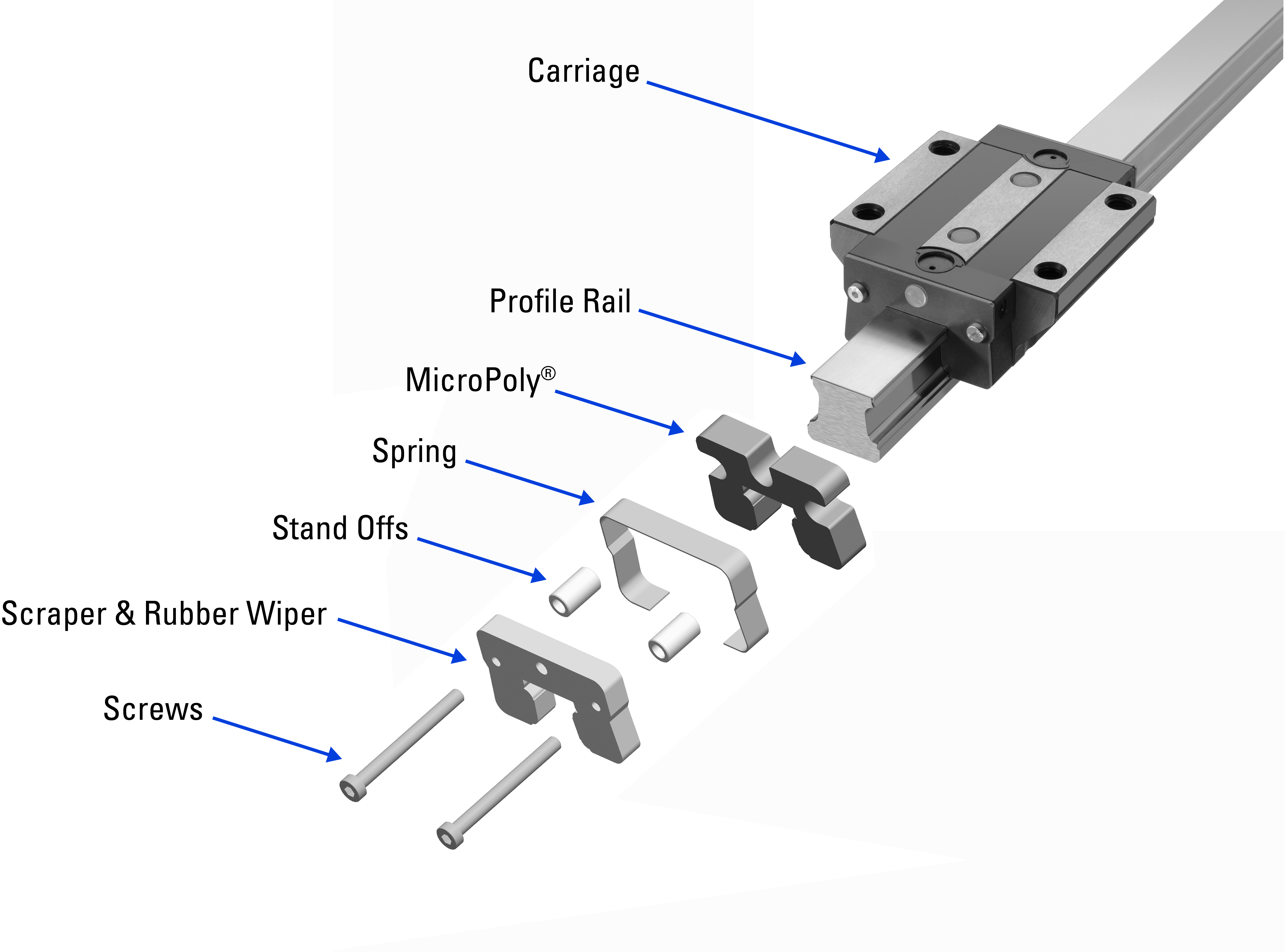

Self-lubricating bearings commonly used in linear and profile rails are made of oil-impregnated plastic. Figure 1 shows a self-lubricating cartridge that might be pressed onto each end of a pillow-block housing of a round rail. In the design illustrated, the micro-porous polymer section is saturated with oil, which gets diffused when the carriage is in motion thanks to the capillary action of a wire spring that is in continuous contact with the rail. This capillary action ensures that there is always a film of lubricant between all rolling elements and races. When motion stops, the micro-porous polymer acts as a sponge to reabsorb the oil, preventing excessive build-up of the lubricant on the shaft and eliminating the messy dripping that comes with manual oil applications. A double-lip, nitrile seal provides further protection from oil loss. Figure 2 illustrates a comparable self-lubricating assembly on a profile rail.

Figure 1. The-oil saturated polymer provides self-lubrication and increases the life of this Thomson Linear Ball Bushing® bearing pillow block by more than 200 times that of conventional linear bearings.

Figure 2. Self-lubricating assembly on a profile rail to ensure constant and even lubrication (image courtesy of Thomson Industries, Inc.).

Specifying self-lubricating bearings

Whether you are an OEM motion designer seeking to design a maintenance-friendly system or a maintenance engineer replacing a bearing that requires manual lubrication, the design and application factors you must consider are similar. Maintainability adds a critical dimension to the specification matrix, impacting — or being impacted by —almost every variable. Self-lubrication options should be considered for just about every profile or linear guide specification and evaluated based on the following criteria:

- Availability of maintenance support — Where end-user maintenance resources are limited, lubrication-free bearings are an easy choice. Independent testing commissioned by Thomson Industries showed that self-lubricating bearings exhibited no need for maintenance or addition of lubrication to the lube block during a three-million-cycle deflection test.

- Lifecycle — The possibility of consistent performance and maintenance-free operation can extend the life of the bearing by as much as three times when compared to a bearing that is lubricated just once — and not subsequently — during installation.

- Accessibility — One of the key factors in determining whether to specify a self-lubricating bearing is the location of the bearing on the equipment. The more disassembly and reassembly required to access the bearing for lubrication, the more time and money will be saved by eliminating the need to maintain that bearing.

- Temperature — Vendors will rate their bearings for operation in certain ranges. Operation outside those ranges could result in bearing failure. Some lubricants, for example, will dry up if operation temperature is too high. A second temperature-related factor is that self-lubricating bearings tend to run faster and thus hotter because there is better control over lubricant build-up, which minimizes dripping. This is not a huge issue but should be considered if the expected operating environment will have temperatures close to what the vendor recommendations.

- Extension — The addition of lubrication bushings to the pillow block can add length to the system, since they are often added on both ends of a carriage. It is seldom much more than a few millimetres, but in tight quarters or where extension flexibility is limited, it could be important. A precise analysis of space requirements is critical to specifying self-lubricating bearings.

- Environmental constraints — The environment in which the bearing will operate also impacts its maintenance-free capability. Operation in areas with high particulate counts or excessive grease and grime, for example, may require some bearing maintenance, but this can be kept to a minimum. The Thomson self-lubricating block shown in Figure 1, for example, uses a solid lubricant that is a mixture of polymers, oils and select additives that reduces the penetration of dirt, grit and liquids into the ball path, preventing premature failures. Installing the self-lubricating blocks with optional accessories can provide even greater protection from environmental assault. Stainless steel scrapers help push larger dirt particles, metal shavings or chips away from seals. Standard bellows can cover a rail for additional protection from particulates as well as splashes.

- Total cost of ownership — While purchase price of a self-lubricating bearing might be 10 to 30 percent higher than the cost of a bearing requiring manual lubrication, the reduced labour costs, elimination of need for lubrication assemblies, improved performance, and reduced downtime, more than compensates for it. Poor lubrication is implicated in half of all bearing failures.

Self-lubricating pillow block assemblies, open or closed, are commonly available with loads ranging from 1110 N to 17800 N but can be customized. Pillow blocks can be integrated in the factory or retrofitted.

With inadequate lubrication being the most common and readily preventable cause of reduced bearing life and failure, the more cost effectively you can optimize the lubrication process, the more bottom-line impact you will enjoy. In addition to maintenance savings and longer life, the lube-free bearings eliminate the need for expensive lubrication systems and the cost of lubricant itself, promising more environment-friendly operation. By considering the factors mentioned above early on in the process, maintenance costs can become one less thing motion control users will have to worry about as they automate critical processes.

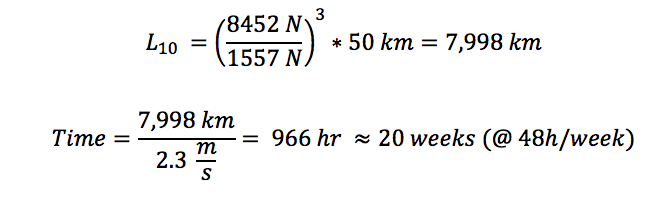

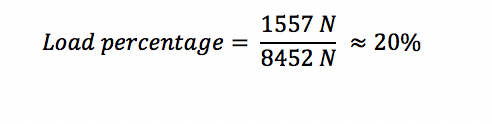

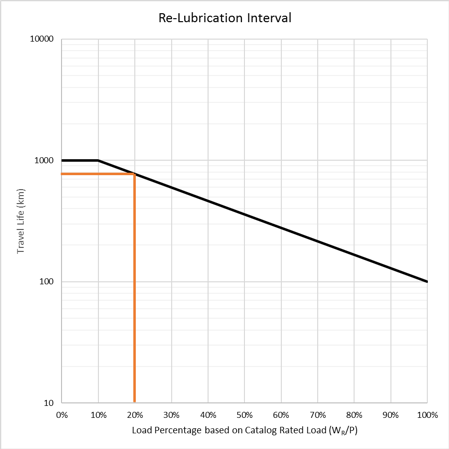

Example 1: For a bottle company, assume they have automated equipment that uses Thomson Super Smart bearings at 1557 N force-applied load and a speed of 2.3 m/s. Linear bearing operating temperature is below 70°C. Application cleanliness is considered high.

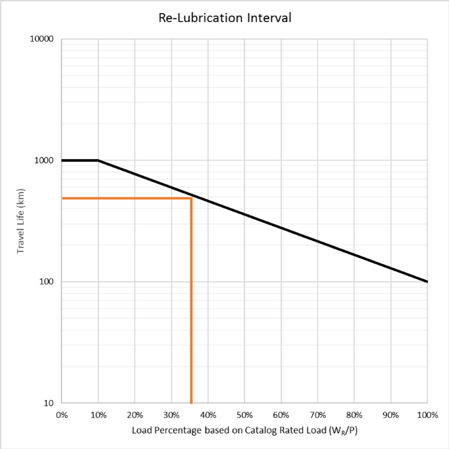

First, they will estimate the expected life (L10) for this application. Catalog rated load: 8452 N (SSU16) and 48 hours per week.

This means that 90% of the bearings will last longer than 20 weeks for this application.

Next, they will estimate the appropriate re-lubrication interval for this application.

Estimated Lubrication Interval=800 km

This means that they will need to re-lubricate the bearings every two weeks for five months before replacing them. The company will experience short maintenance cycles and high maintenance costs. Also, there is a substantial risk to skip bearing re-lubrication, which leads to unplanned downtime that can easily cost more than $10,000 per hour. All of this can be avoided by including the lube-for-life option.

Example 2:

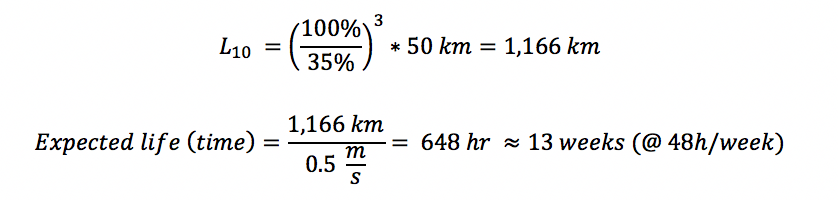

A fully automated system contains 20 bearing axes with 3-4 bearings per axis and 60-80 bearings in total. Bearings are loaded at 35% of rated load (@50 km), and light contamination may occur. Operating temperature is below 85°C. Typical linear bearing speed of 500 mm/s.

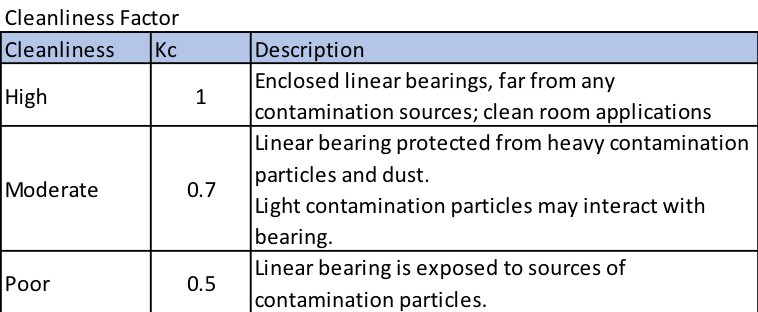

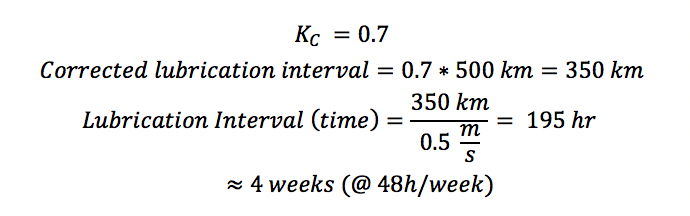

Based on applied load, as percentage of catalog rated load, and moderate cleanliness, we can estimate the re-lubrication interval for linear bearings as follows:

Estimated Lubrication Interval=500 km

Adding a lube-for-life feature to bearings in this system can increase the lubrication interval more than three times, which easily translates into dollar savings on maintenance fees and machine downtime