Designing Smart Machines Starts with Smart Tools

As the industrial world becomes increasingly connected, the designer’s need for intelligent components that can communicate with each other and operate without the need for manual interaction is growing. Thomson, a trusted manufacturer that has always been committed to staying ahead of the technology curve, is meeting this demand and helping to usher in a new generation of “smart” actuators.

What are Smart Actuators?

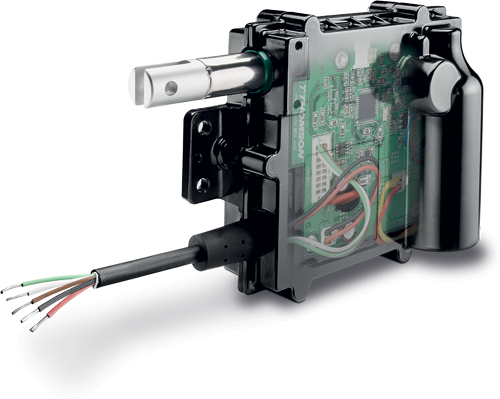

The crux of smart actuators begins with the integration of onboard electronics, which enables enhanced control functions that were previously external directly into the actuator. These functions include:

- Switching

- Position feedback

- System diagnostics

Newer, integrated actuators from Thomson incorporate microprocessor-based printed circuit boards with complimentary software that allows communication between remote networks.

Benefits

- Increased efficiency and productivity.

- Enhanced diagnostic capabilities and controllability.

- Fewer components and less cabling.

- Minimized complexity and easier installation.

- Reduced hardware and software costs.

- Decreased machine development time and weight.

- Improved machine functionality and performance.

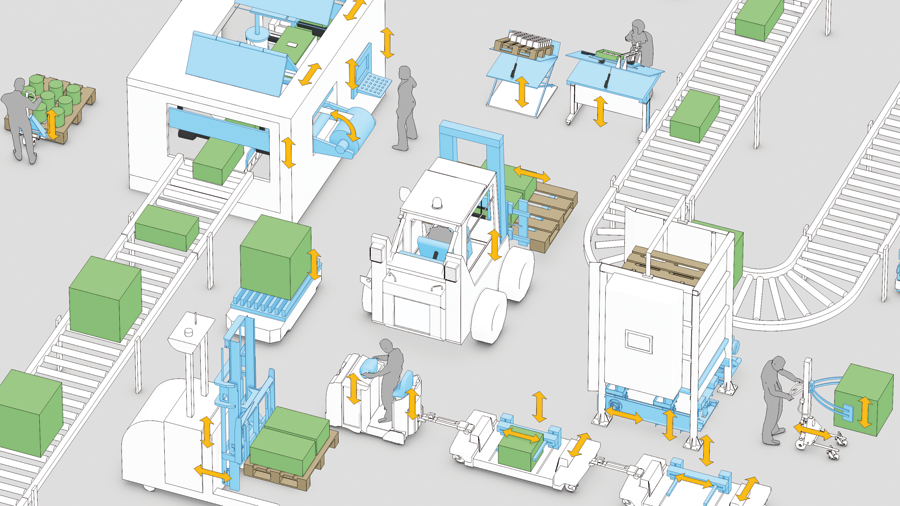

Smart actuators are increasingly finding their way into applications that were once dominated by pneumatic and hydraulic systems. The mobile off-highway (MOH) vehicle market was among the first to deploy electric actuators for enhanced control and automation capabilities available in the field. However, other industries have befun to realize the many benefits of smart actuation.