Linear Slide Bearings

Thomson invented the Linear Ball Bushing® Bearing more than seven decades ago, and we’ve been recognized as the global leader in linear slide bearing technology ever since. We offer the world’s largest selection of state-of-the-art linear bearings and accessories, which have been manufactured to the highest quality standards to meet specific design requirements. Discover which linear components are ideal for your next designs.

Why choose Thomson linear slide bearings?

No matter your application requirements, Thomson offers a linear slide bearing to deliver the solution. All families of our linear bearings have been engineered for low friction and smooth, accurate motion. Plus, when used with our popular 60 Case® LinearRace® shafting, Thomson Ball Bushing Bearings last up to 50% longer than the competition.

Which Thomson linear slide bearing is right for your application?

Super Smart

Using patented self-aligning, double-track linear bearing technology, which increases the load carrying capacity by six times and increases travel life by 216 times compared to conventional bearings, Thomson Super Smart linear slide bearings can maintain their diametrical fit when installed in housings that are slightly out of round. To minimize installation time and cost, Super Smart bearings can be ordered factory installed in an industry standard single or twin pillow block configuration.

Super

Offering three times the load capacity or 27 times the life of conventional linear bearings, the Super bearings are self-aligning, lightweight and adjustable with a low coefficient of friction. A quick and easy replacement for high-friction plain bearings, Super linear slide bearings feature wear-resistant, engineered-polymer retainers and outer sleeves to reduce inertia and noise in critical, high-speed applications.

Precision Steel

Available in open, closed, extra precision and adjustable versions as well as factory installed in a malleable iron pillow block, durable Precision Steel linear bearings eliminate binding and chatter, making them ideal for replacing plain bearings in harsh and high-temperature applications

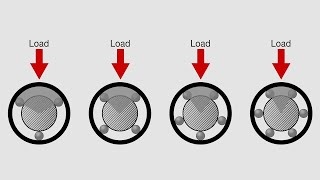

MultiTrac®

Extremely rigid, MultiTrac linear slide bearings reduce deflection and provide twice the load capacity or eight times the travel life of conventional metric linear bearings. Their patented ball control technology eliminates binding and chatter, which are common with high-friction, plain bearings.

RoundWay®

Boasting more than 20 times the load capacity of a conventional linear bearing, RoundWay linear roller bearings allow designers to optimize system compactness and minimize hardware costs. These bearings combine the high load capacity of hardened and ground steel recirculating rollers with a rigid malleable iron mounting block. The chain-connected rollers allow the RoundWay to travel at extremely high speeds in unforgiving, contaminated environments.

FluoroNyliner®

Ideal for washdown or submerged environments, FluoroNyliner linear bearings are self-lubricated with a large contact surface for high performance in high vibration or impact applications. Their simplified, corrosion-resistant design allows them to run in highly contaminated conditions.

Miniature Instrument

High accuracy and compactness make Miniature Instrument linear slide bearings ideal for small mechanisms or devices that require high repeatability and responsiveness. When replacing high-friction plain bearings, Instrument bearings’ consistently low coefficient of friction eliminates chatter and provides smooth linear performance.

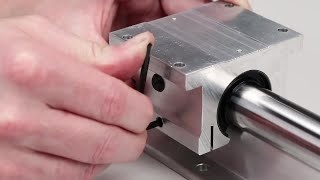

Square vs. Round: Which Linear Guide is Best for Your Application?

When specifying linear guides for your applications, there are two types from which to choose: square (profile) guide rail and round guides (shafting). Your application will dictate which type of linear guide should be used.

Square guide rail is well suited to high-load applications that require good rigidity and high accuracy. These linear guides achieve their performance through the precise grinding of the ball tracks in the rail, which have close conformity to the balls. The classic application for profile rail bearings is in the machine tool industry, where load capacity, rigidity and accuracy are paramount. Round guides offer several advantages of their own, including the ability to run smoothly when mounted to less-than-perfect surfaces or used for vertical movements with heavy loads.

For a more detailed analysis of choosing square or round linear guides, click here.