Choose Your Login Account

Thomson currently has two account systems - one for the website and CAD model downloads, and one for e-commerce. We understand that two logins is an inconvenience and are working to consolidate our systems into one login process. Until we’re able to consolidate the two logins, please follow these guidelines:

- Download CAD models

- Save and retrieve projects in LinearMotioneering® and MicronMotioneering® tools

- Access Distributor Extranet and all related resources

- Order directly from Thomson online (North America only)

- Authorized Thomson Distributors can view and order from quotes online (Global)

- View the shopping cart and look up prior direct orders

Vue d'ensemble

Why Choose Ball Screw Assemblies?

Ball screw assemblies provide an excellent method for translating rotational motion to linear motion for many applications, including those where high loads and close tolerances are required. To apply the correct type of ball screw and nut assembly in a particular application, the design engineer must consider the advantages and capabilities of each. Selecting the right technology can reduce design complexity, improve performance and reduce the overall cost of the assembly.

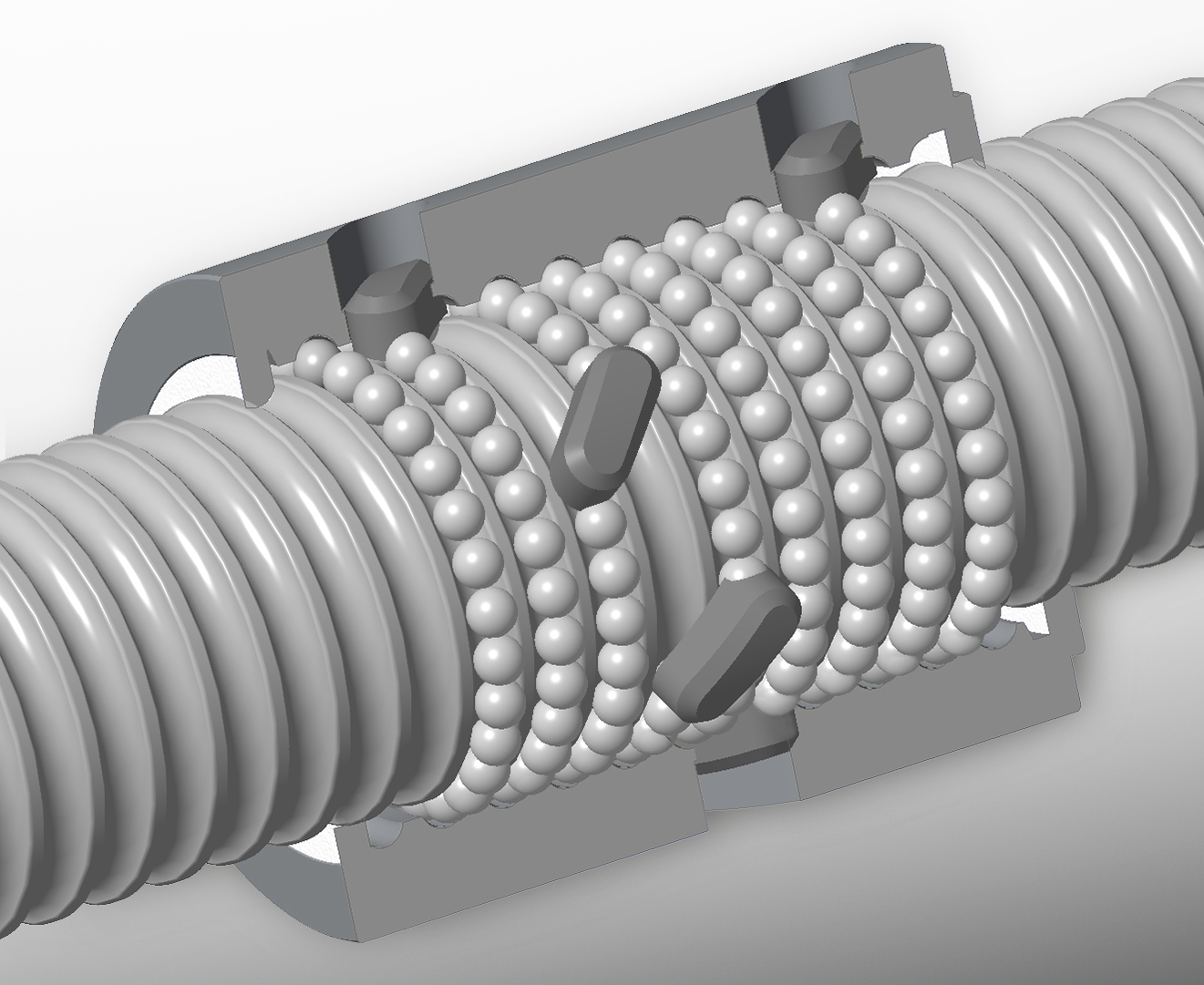

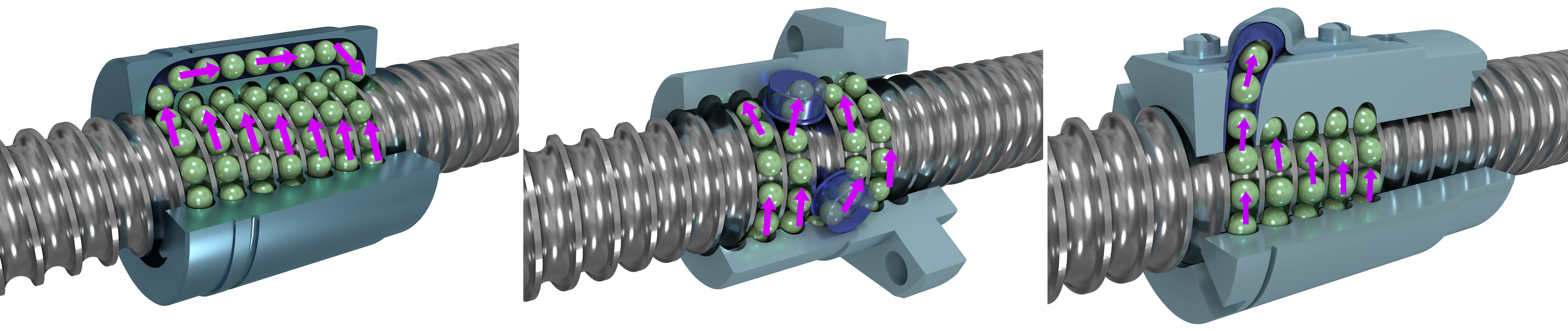

This image compares the three types of ball return systems (from left to right): internal, button and external.

Mounting Options

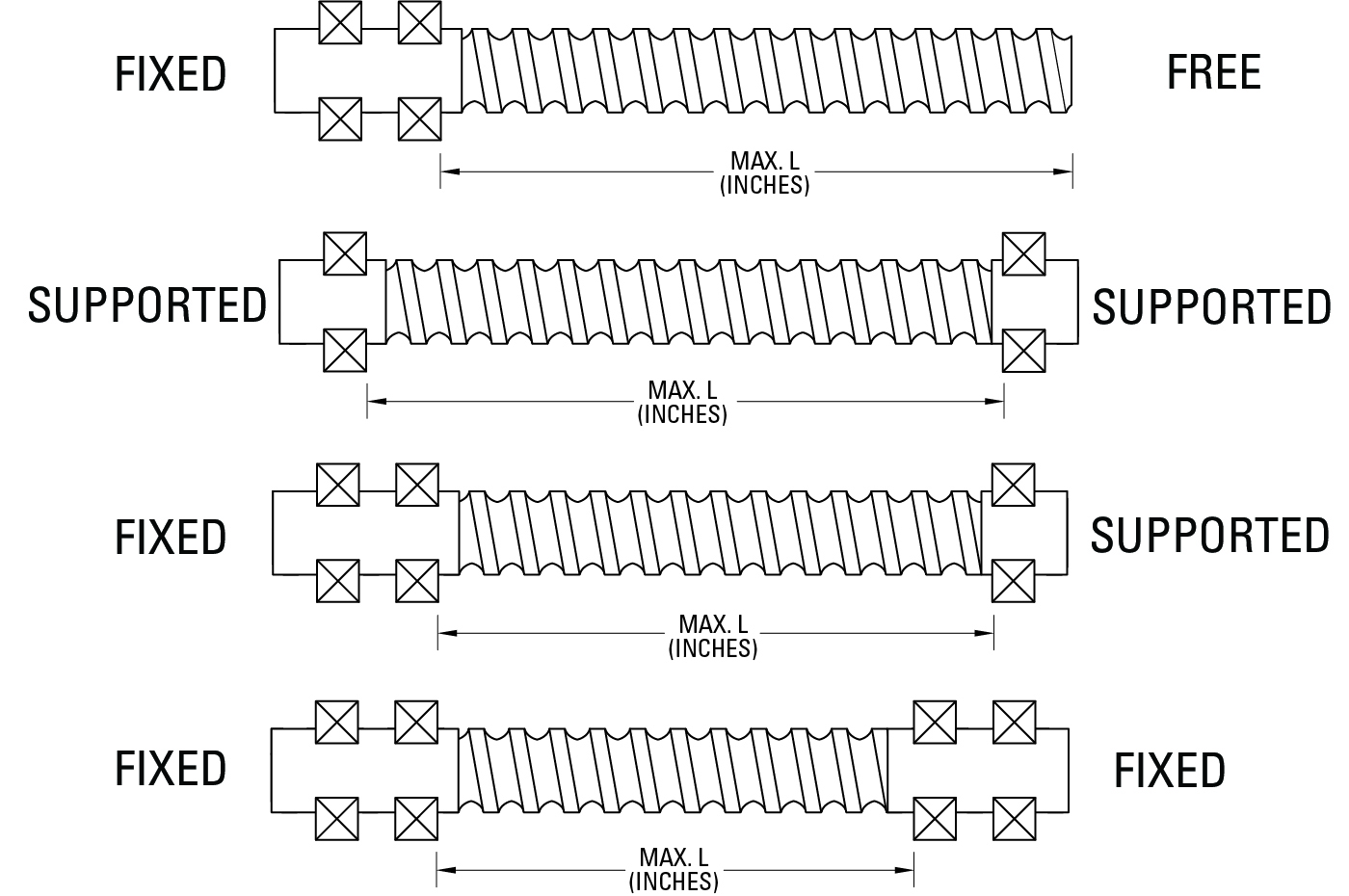

Ball screws are mounted in either supported or fixed configurations. A supported end holds the ball screw at one focal point and does not resist bending moments. A supported end is generally easier to align and install than a fixed one, so installation costs are typically lower. A fixed end resists bending moment loads because it is typically based on two bearings spaced sufficiently so the ball screw remains perpendicular to the planes of the rotary bearings. The fixed offers greater column strength and higher critical speed. The image below illustrates four fixity options.

The assembly can be fixed at both ends, fixed at only one end and supported on the other, supported at both ends, or fixed at one end and free at the other.

Ball screw assemblies are not all alike. Whether it be metric ball screws, inch ball screws or miniature ball screws, key differences affect their performance and extend their lives. These include:

- Design. Through extensive research and evaluations, Thomson engineers have been able to develop a comprehensive ball screw offering that delivers optimal solutions for countless applications. Available in a full range of diameters, leads and ball nut configurations, in either pre-loaded or non-pre-loaded types, and all in industry standard envelopes, our ball screws provide dependable accuracy and repeatability at an economical price.

- Quality. With a vast background in countless applications, Thomson is uniquely positioned to provide the highest levels of quality across our full line of ball screw assemblies. Our fully equipped engineering laboratory performs qualification testing for mechanical performance, environmental effects and structural integrity. Your rotating ball screw nut assembly is inspected every step of the way to ensure top quality and performance.

- Materials. The materials used to manufacture ball screw assemblies are critical to their performance. Our in-house metallurgists control and verify that the materials used are of the highest quality. They can also select and recommend materials best suited to your particular application.

- Manufacturing. Thomson maintains the most modern and complete ball screw manufacturing facilities in the industry. In-house manufacturing capabilities include our proprietary heat treating and plating processes. Expert manufacturing using the most modern equipment available provides ball screw assemblies that set the standards for performance, precision and travel life.

- Application Support. Working with Thomson is like having your own staff of ball screw design engineers able to address application concerns and recommend solutions. Thomson field sales and applications engineering personnel have more ball screw expertise than any other group in the industry. They are skilled at evaluating your requirements and designing assemblies that fit your needs.

Avantages des vis à billes Thomson

VIDÉO : Vérins intelligents Thomson : pour concevoir des machines intelligentes avec des outils intelligents

VIDÉO : Maximisez la capacité de charge, le cycle de vie et la compacité de vos produits de mouvement linéaire

Chaque nouvelle application exige une analyse minutieuse des performances, du cycle de vie et du coût des produits. En particulier de ceux qui sont amenés à supporter des charges élevées. Découvrez pourquoi vous devriez envisager d'utiliser une vis à billes à charge élevée au lieu d'une vis à billes standard dans votre prochaine application de mouvement linéaire.

Présentateur : Markus Brändle, Spécialiste gamme de produits – Vis, vérins à vis et LB&G Thomson Neff Industries, Allemagne

VIDÉO : Conseils techniques : comment charger des roulements à billes dans un écrou à billes métrique

Comment recharger les roulements dans un écrou à billes à retour par bouton. Les écrous à billes métriques sont souvent à retour par bouton. Mais cette technique peut également être utilisée sur les écrous à billes à retour par tube.

VIDÉO : Considérations et calculs pour choisir la vis à billes adaptée à votre application

Parmi les milliers de choix possibles, comment dimensionner et trouver rapidement et sans risque de se tromper la solution de vis à billes optimale pour votre application de mouvement linéaire ?

VIDÉO : Conseils pratiques : comment remplacer un écrou à billes par une vis à billes

Comment installer un écrou à billes sur la vis d'un arbre lisse.

Articles techniques

-

Vis à billes en pouces et métriques : vous posez-vous les bonnes questions ?

Étant donné que les vis à billes sont disponibles en dimensions impériales et métriques, les concepteurs commencent parfois le processus de spécification en sélectionnant une gamme de produits sur la base de l'unité de mesure. Cette approche présente le risque d'exclure prématurément le produit idéal pour l'application et d'entraîner des pertes considérables en temps, main-d'œuvre et coûts. Cet article explique comment en centrant les questions de dimensionnement et de choix sur les performances plutôt que sur le nom des produits, il est possible de créer des solutions de mouvement linéaire plus efficaces.

En savoir plus -

Vis à billes à charge élevée - La solution de commande de mouvement à haute densité de charge

Les vis à rouleaux sont souvent présentées comme étant la seule technologie à même de supporter des charges élevées dans les applications soumises à une contrainte de taille. Toutefois, les progrès réalisés dans la technologie des vis à billes les rendent désormais également compatibles avec des applications impliquant des charges élevées. Cet aspect est important, car une vis à billes à charge élevée coûte habituellement deux fois moins cher qu'une vis à rouleaux comparable à performances équivalentes.

En savoir plus -

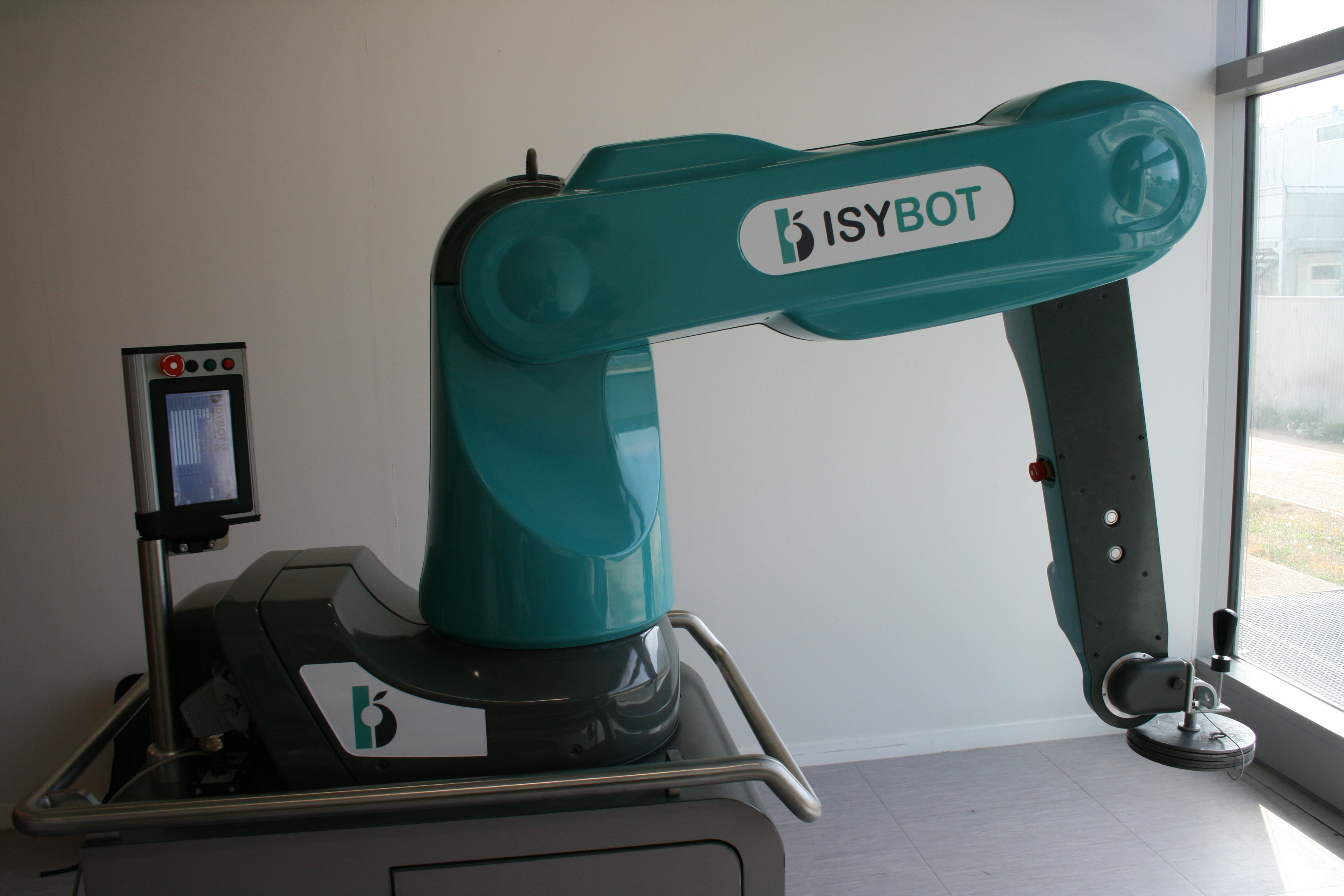

Vis à billes – Une solution pour des mouvements fiables et efficaces dans les robots collaboratifs

Utilisés dans les applications de production à grande échelle comportant des opérations de levage continues mais toujours susceptibles de nécessiter une intervention humaine, les robots collaboratifs (cobots) sont de plus en plus répandus. Un fabricant français de cobots a élaboré une solution faisant appel à des vis à billes et à des vérins à câble au lieu d'engrenages et qui fait figure de référence en termes d'efficacité et de sécurité des cobots.

En savoir plus

Brochures

Catalgues

| Vis de précision | 7869 KB | |

| Vis de précision | 7890 KB | |

| Vis de précision | 6598 KB |

Manuels

Technical Articles

| Thomson High-Load Ball Scews Provide Maximum Load Capacity and Longer Life in a Compact Envelope | 2019-02-04 |

Certifications

To provide better service to you on our websites, we and our service providers use cookies to collect your personal data when you browse. For information about our use of cookies and how to decline them or turn them off please read our cookie policy [available here].