Why the Glide Screw™?

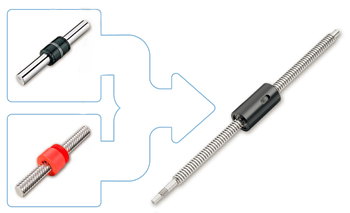

The Thomson Glide Screw is a breakthrough in linear motion technology that combines the best features of a linear bearing and a lead screw into something better than both. The patent pending Glide Screw delivers high performance, fast installation and less complexity in a small package.

Designing the Glide Screw into your equipment can help you deliver a solution that is more compact and reliable, and provides an overall lower total cost of ownership . It’s easy to make the change from traditional solutions with stocked standard sizes and quick availability of custom solutions with help from a Thomson applications engineer.

Choose the solution optimized for today’s designs. Choose Glide Screw.

Reduced footprint

- Integrated lead screw / linear bearing

- Side load / moment load capable

Reduced equipment downtime

- Fewer failures with pre-aligned screw and bearing

- Component alignment is not critical – smooth and quiet motion

- Maintenance free with Thomson Lube-4-Life lubrication block standard

Lower cost of ownership

- Faster installation

- Fewer components for a simpler bill of material

- Maintenance free! No lubrication required

Standard products in stock

- Inch Series includes 3/16”, 1/4” and 3/8” nominal diameters

- Metric Series includes 4, 6 and 10 mm nominal diameters

- Flanged and cylindrical nut bodies standard

Options for harsh environments

- High temperature resistant – inside ovens or autoclaves (up to 175°C)

- Clean room – in robot vacuum chambers, laboratories or medical equipment (class 1000)

- Food grade – in packaging and food processing equipment

Custom products available

- Nut configurations

- Screw diameters

- Thread leads

- Custom changes

Easy to install

- All that is required is a Glide Screw and an anti-rotation feature

- No need for reference surfaces or the pain of “floating” your system into alignment